Innovative stair mould enables industrial production from batch size 1

Innovative integrated staircase production

You have probably often thought about how much time and money you invest in staircase production. REPRECT offers you a revolutionary solution that covers the entire production process – from batch size 1!

With our system, you can reduce your labour and material costs by 30–50%. With REPRECT this vision becomes reality! Our innovative industrial staircase production enables you to work more efficiently while guaranteeing the highest quality. Our consultants are available on site to customise the process to your needs.

Staircase production redefined:

Modular, sustainable, efficient

With REPRECT you benefit not only from a comprehensive transfer of expertise, but also from quality assurance through traceable processes. Our continuous further development ensures that you are always at the cutting edge of technology. You can also enjoy regional exclusivity on request – a clear competitive advantage for your company!

Planning – statics – reinforcement – stairs – formwork – storage

Get in touch with usto find out more about our customised solution for staircase production. Let us optimise your production processes together and reduce your costs.

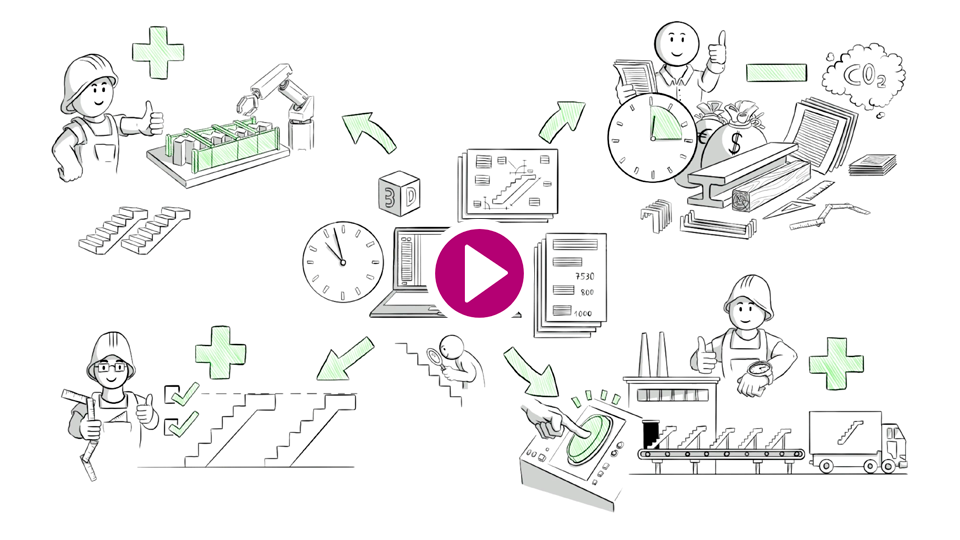

Advantages of an industrial staircase production system

Customised manufacture

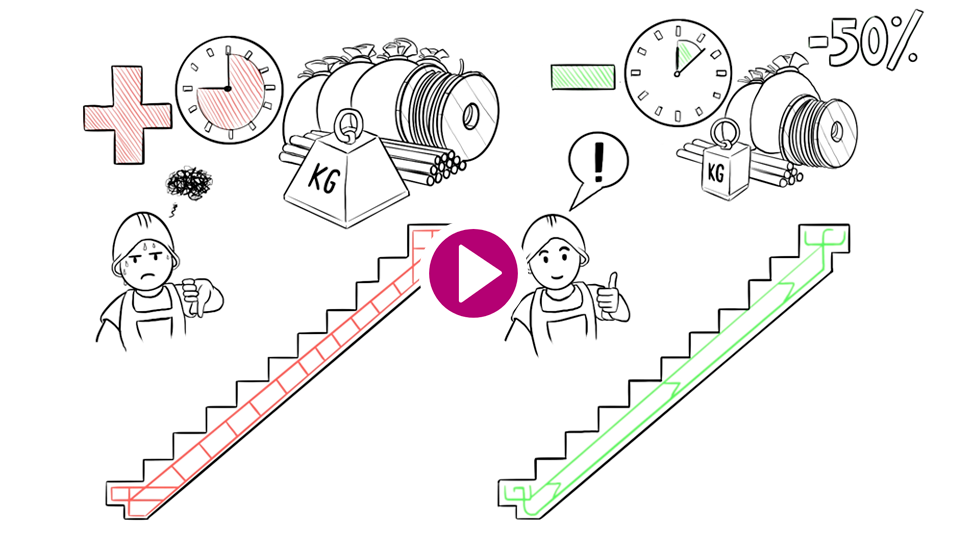

Revolutionise your processes with the REPRECT TOPSTEPS staircase production system and take reinforcement production and reinforcement optimisation to a new level.

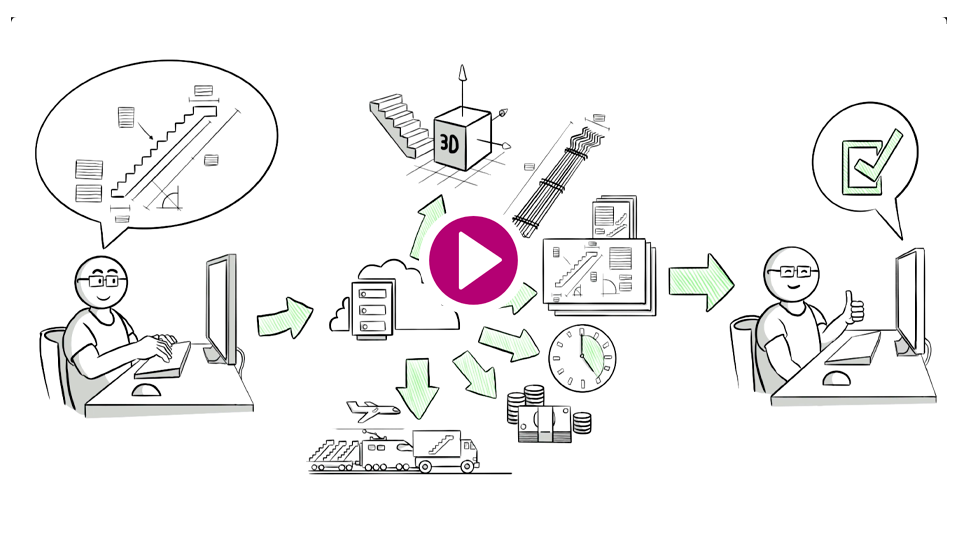

Production data automate

Automate the production process for your concrete stairs and generate all production data fully automatically with the REPRECT TOPSTEPS Software.

Just-in-time production

Optimise your production processes, increase your flexibility and reduce warehousing, lead times and delivery times with REPRECT TOPSTEPS.

Increase personnel efficiency

Increase your personnel efficiency and realise every step of your staircase production with just one person – thanks to REPRECT TOPSTEPS.

More sustainable production

Save up to 50% in material and reduce your CO₂ emissions with the revolutionary REPRECT TOPSTEPS Technology.

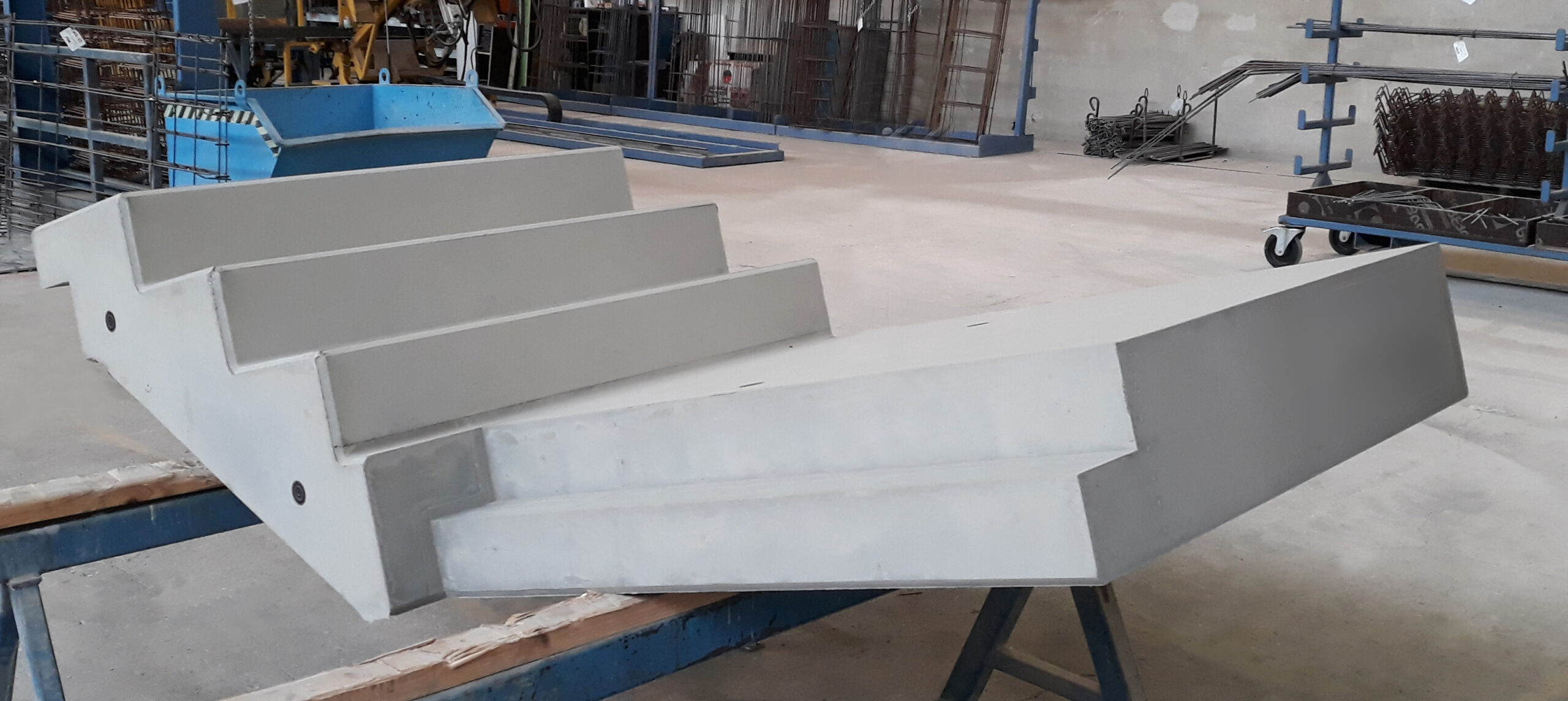

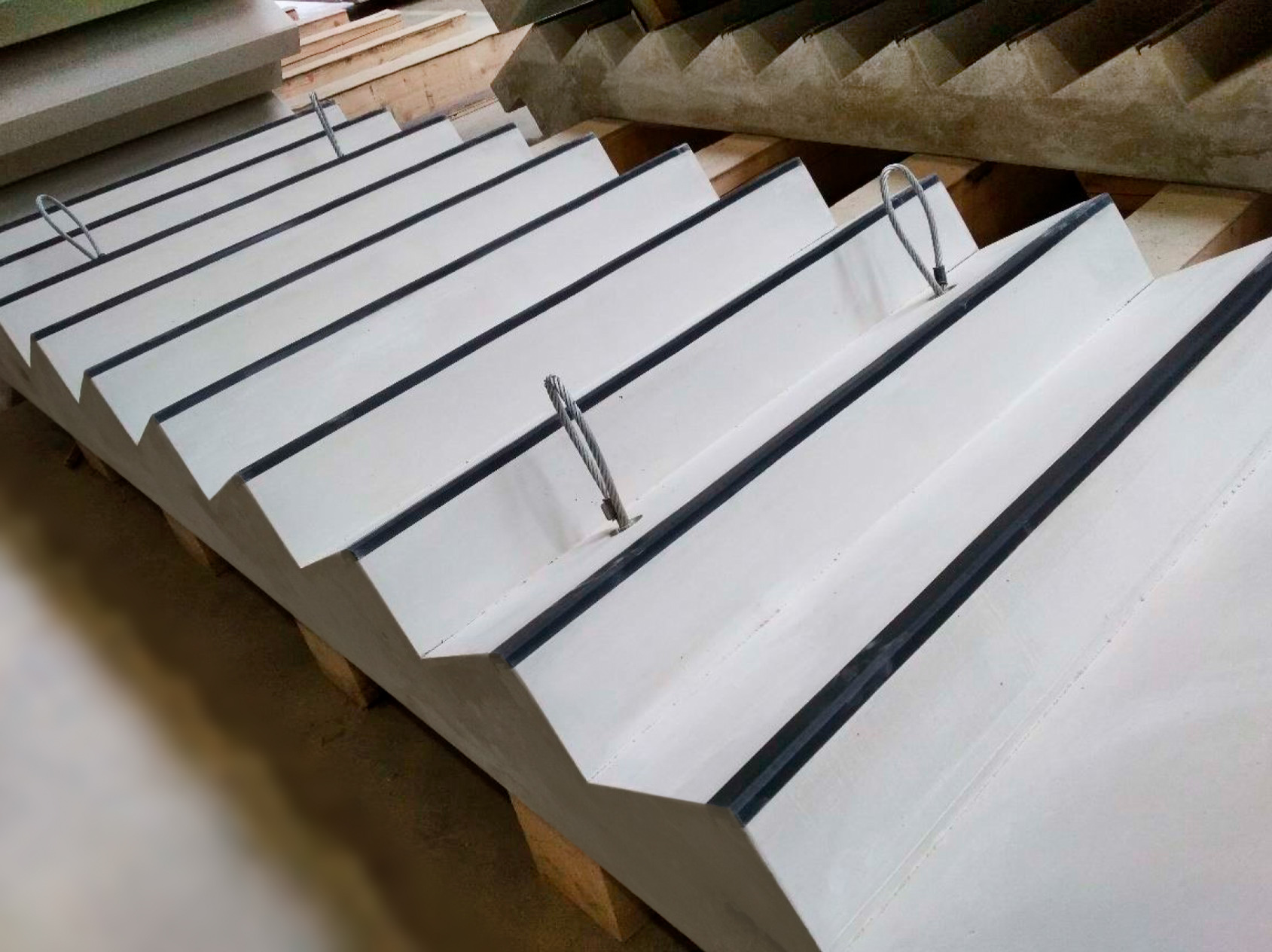

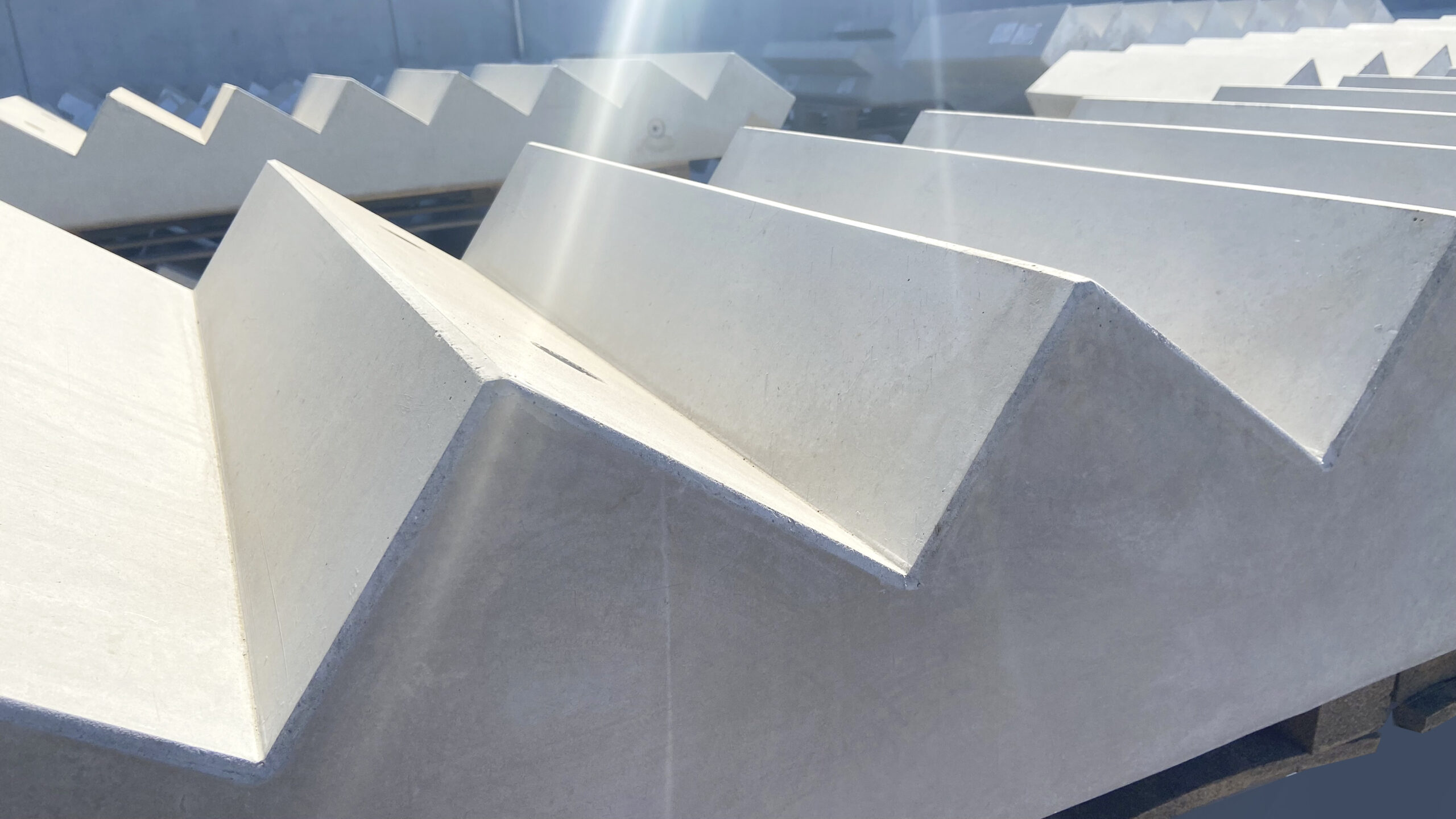

Inspire with quality

Convince with a five-sided clean surface with exact stair geometry and optimised reinforcement position with REPRECT TOPSTEPS.

Your advantages at a glance

Advantages of just-in-time staircase production (33 sec.)

Software for automated data generation (29 sec.)

Optimised reinforcement production (34 sec.)

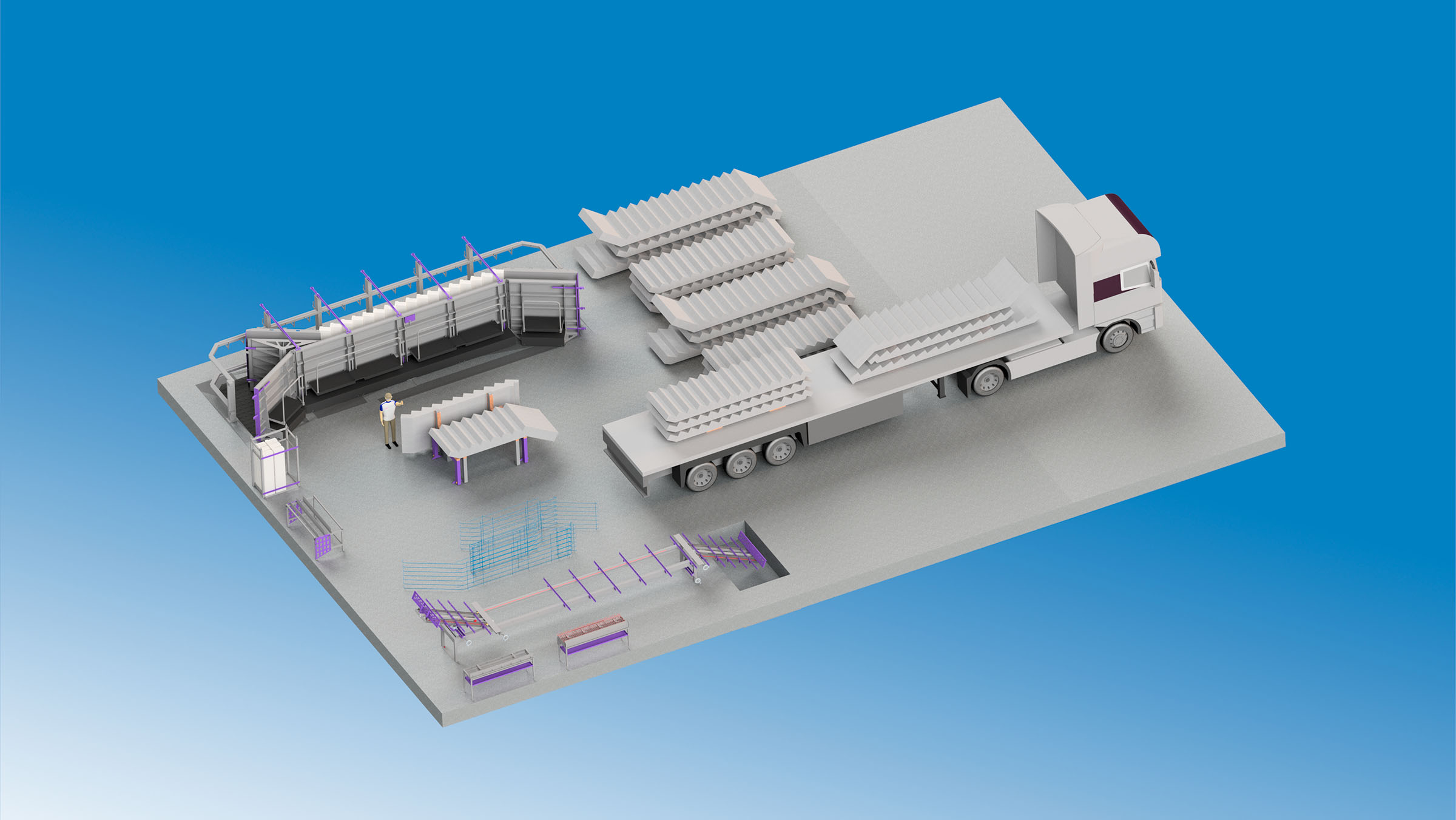

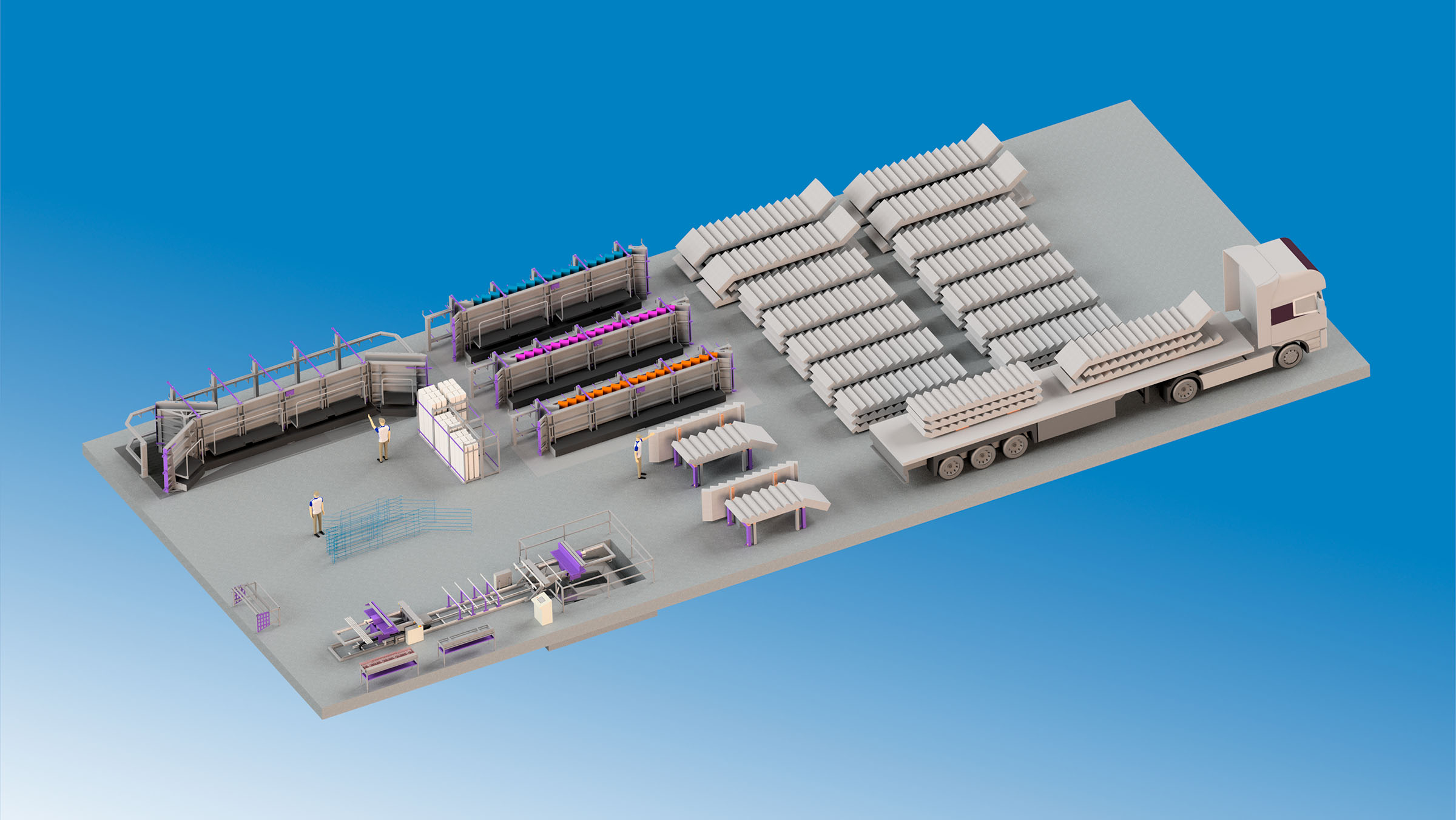

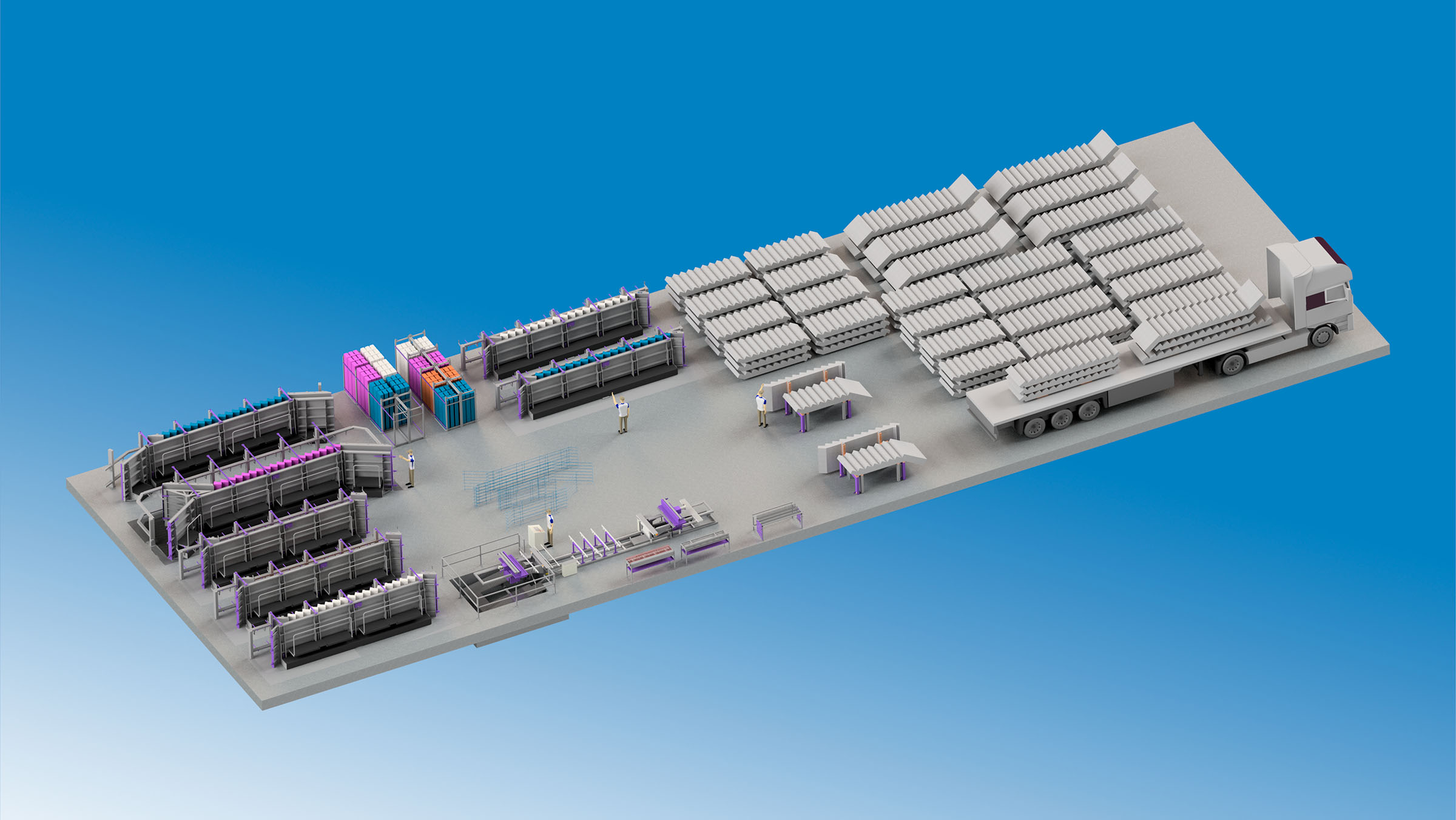

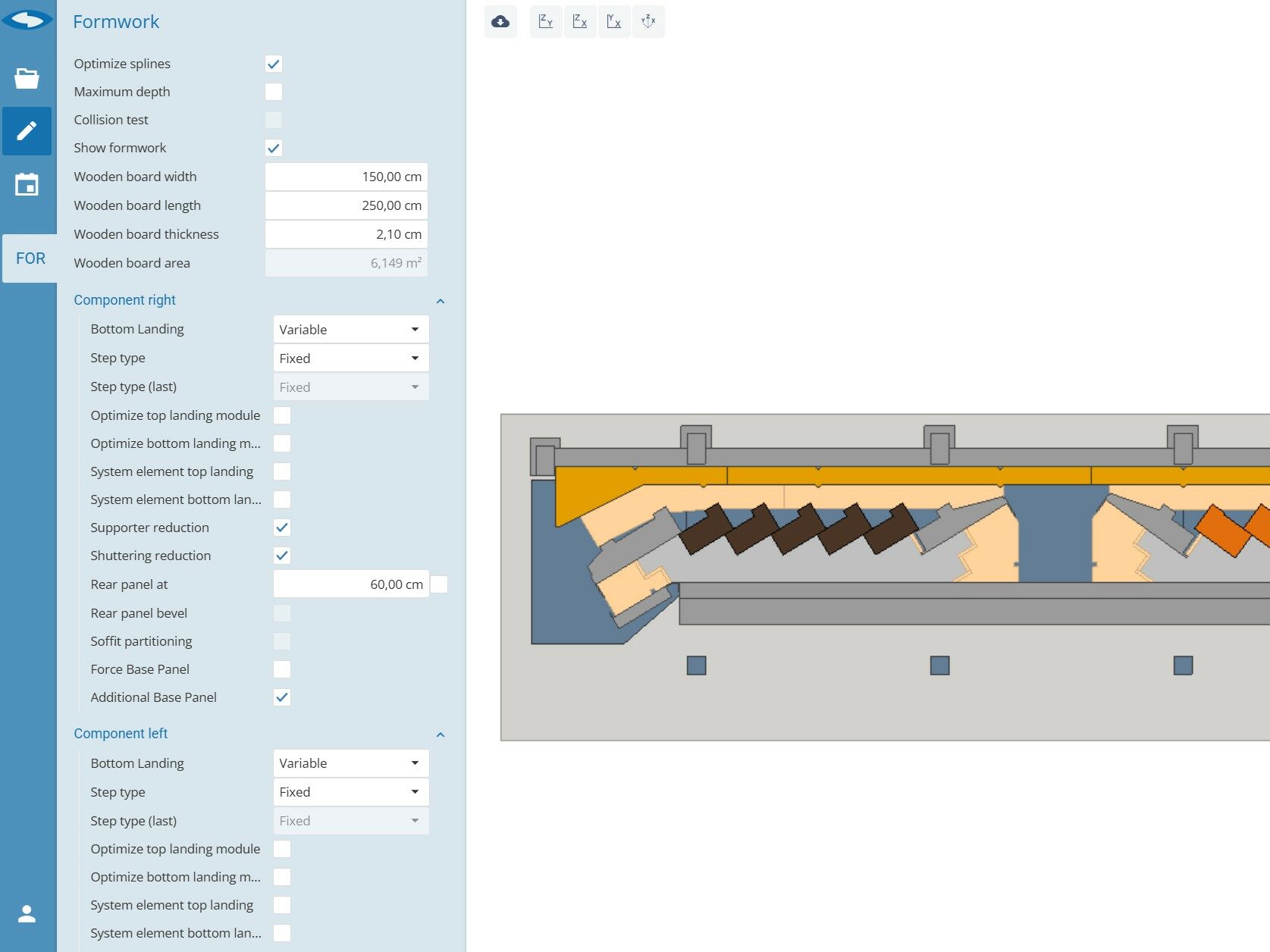

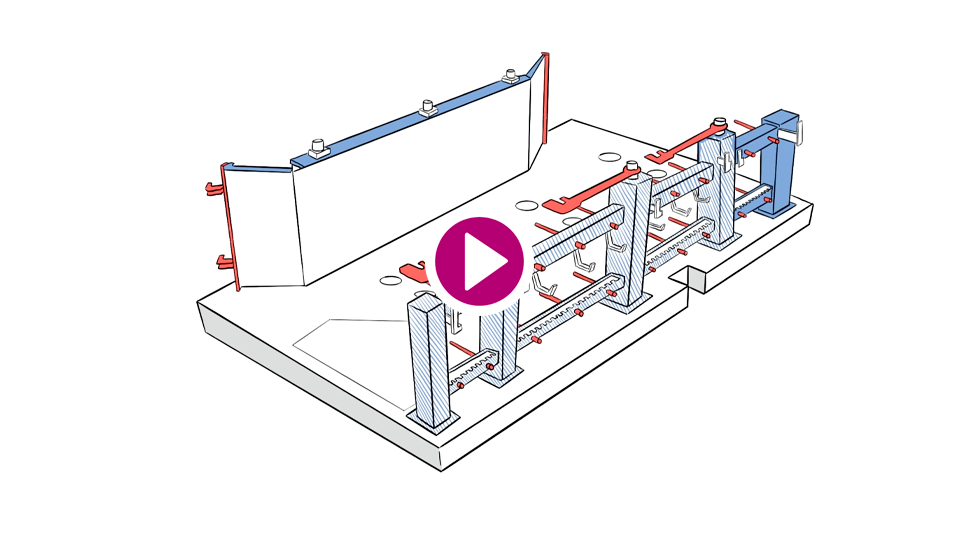

Innovative formwork technology (35 sec.)

A revolutionary staircase manufacturing system (3 min.)

FAQs

What is this REPRECT-system?

The REPRECT-system is a patented, integrated production system for the manufacture of straight and spiral precast concrete stairs with optimised processes. It includes a new type of staircase formwork, reinforcement technology and reinforcement production, proprietary software for factory planning and supplementary production equipment.

How does it work REPRECT-system?

The customised REPRECT With our own production system, consisting of modular staircase formwork systems (supported by CAD-CAM technology), special reinforcement technology and reinforcement production, as well as our own software for factory planning, customised staircases (even for batch size 1) can be produced quickly and easily.

What are the benefits of the special software?

By entering predefined geometry data, the software generates all the data required for production. This includes geometry, reinforcement plans, formwork plans and machine data.

How does the system reduce storage costs?

Thanks to the quick and easy formwork conversion, the required stairs can be produced as and when needed. This enables just-in-time production.

How does the system contribute to sustainability?

Reduced steel consumption by up to 50% with simultaneous CO₂ emission reduction, minimised material consumption, efficient production processes and reduced warehousing

How long does it take to produce a simple straight staircase?

For a simple staircase with 8 heights and a width of 1.00 m, the entire production process, including reinforcement and new formwork adjustment, can be completed in approx. 3.5 hours.

Can the system be used for different types of stairs?

Yes, it is designed for both straight (with and without a landing) and spiral staircases.

Which materials are saved?

Savings are achieved in the reinforcement (up to ‑50% reinforcement content) and in the formwork setting (up to 70% timber compared to conventional timber formwork).

What certifications are available for the system?

The reinforcement technology is based on our own type statics, which are based on Eurocode 2 and are approved in several European countries.

How is the surface quality of the stairs ensured?

The upright production of straight staircases creates a 5‑sided clean surface.

The spiral staircases are concreted negatively. The treads and risers are smooth and the underside must be levelled or smoothed.

Which companies can benefit from REPRECT benefit?

Our production systems are aimed at precast concrete plants worldwide that already manufacture stairs, want to expand their product portfolio or want to establish themselves on the market as a newcomer.

What cost savings are possible with the system?

Depending on the initial situation, material savings of up to 50% are possible for steel, up to 70% for wood and up to 50% for labour costs of 20%.

What costs can be expected?

The costs for the hardware (formwork, reinforcement machines, etc.) vary depending on the customer’s equipment requirements.

The entry-level price for the REPRECT TOPSTEPS A licence fee is charged for the expertise and software. This depends on the size and possible exclusivity of the licence area.