About us

Our history

In 2018 REPRECT was founded with the clear vision of developing and marketing innovative technologies for the industrialisation of construction systems with precast concrete elements.

Alfred and engineer Florian Redlberger developed the vision of revolutionising the entire manufacturing process for precast concrete staircases in order to initiate a sustainable change towards industrial production.

Our founders – experience and innovation combined

Alfred Redlbergeran experienced Austrian entrepreneur and innovator in the precast industry, has extensive expertise in the areas of development, product and production technology. His ability to develop forward-looking solutions is reflected in practical innovations such as the patented TOPSTEPS-system for precast concrete stairs.

With many years of experience in top management and as a management consultant, Alfred Redlberger has successfully realised several patented production and manufacturing technologies. He manages REPRECTtogether with his son, as managing director and partner. He is convinced that „ideas don’t retire” and sees continuous innovation as the key to success.

Engineer Florian Redlberger complements the management team with his sound training as a mechatronics engineer for machine and production technology. He contributes his practical expertise in a targeted manner to drive forward the expansion of digitalised and automated industrial production.

With his technical expertise and extensive practical experience, he implements innovative concepts that optimise the entire production process and pave the way for future-proof developments. Together with his father Alfred, Florian Redlberger shapes the strategic and technological development of REPRECTto keep our finger on the pulse of the times.

Our innovative strength – practical solutions for the future

As part of a research project, comprehensive solutions for the industrialisation of the entire process of manufacturing precast concrete staircases were developed under the leadership of the founders. These practical innovations, which significantly increase both the efficiency and quality of production, are marketed internationally on the basis of licence and know-how agreements. This approach is always characterised by a combination of technical excellence and direct practical relevance – because this is the only way we can meet the challenges of the future.

The developments at REPRECT are designed to optimise the entire production process – from precise planning to the highly automated production of concrete stairs. The focus here is on cost optimisation, simplification of work and environmental compatibility. Our aim is to offer our customers and partners worldwide a future-proof, high-performance solution that sets new standards in staircase production.

Vision

REPRECT – The future of industrial staircase production

We believe in a world in which construction projects are realised efficiently, sustainably and flawlessly. Our aim is to be the market leader in precast staircases together with our partners. Precast concrete staircases are not the alternative – they are the future.

Mission

The way in the future

We are setting new standards in efficiency, sustainability and digitalisation along the entire value chain.

We are shaping the future of staircase production with innovative technologies that are highly automated.

- Technological perfection: We optimise and develop manufacturing processes to produce precast concrete staircases with the lowest possible expenditure of time and resources, with high quality and precision.

- Sustainability & resource efficiency: Our aim is to sustainably reduce the CO2 footprint in staircase production.

- Digitisation: From software-supported planning, including type statics, to CNC-controlled production, we ensure maximum efficiency and quality assurance in every step.

- Worldwide scalability: Our production system makes it possible to offer precast concrete staircases of optimum quality and at competitive prices in all markets around the world.

Maximum efficiency and future-proofing: Our solutions for all common staircase designs enable consistent implementation of cost optimisation, work simplification and environmental compatibility. also for future requirements.

Strategy

Perfection without alternatives: Precast concrete stairs as a global standard

The construction industry is facing huge challenges – from rising costs and a shortage of skilled labour to sustainability requirements.

REPRECT offers an efficient solution with its production system for precast concrete staircases.The combination of state-of-the-art production technology and sophisticated equipment ensures that our solution offers added value to every construction project.

Holistic solutions for the manufacturing process: We offer optimised solutions for all aspects of precast concrete staircase production, ensuring the highest product quality at the lowest possible cost.

International expansion through strong partnerships: We are establishing a global market presence by gaining regional manufacturers of precast concrete parts as partners.

Licence and know-how transfer: We give our partners worldwide access to our expertise and production processes through licence and know-how agreements.

We place TOPSTEPS Precast concrete staircases are internationally recognised as a solution without alternative, which can be realised in all design variants and technical manufacturing requirements.

Values

The industrial Staircase production rethought

- Reliable team: We remain a small, highly qualified team

- Continuous optimisation: We are constantly working on product, cost and process optimisation in order to always provide the best solutions.

- Working in partnership: We actively support our partners in implementing our solutions based on best practices – regardless of their production volume

- Adaptability: Where necessary, we adapt our business model to country-specific circumstances in order to be successful globally.

Licence partner

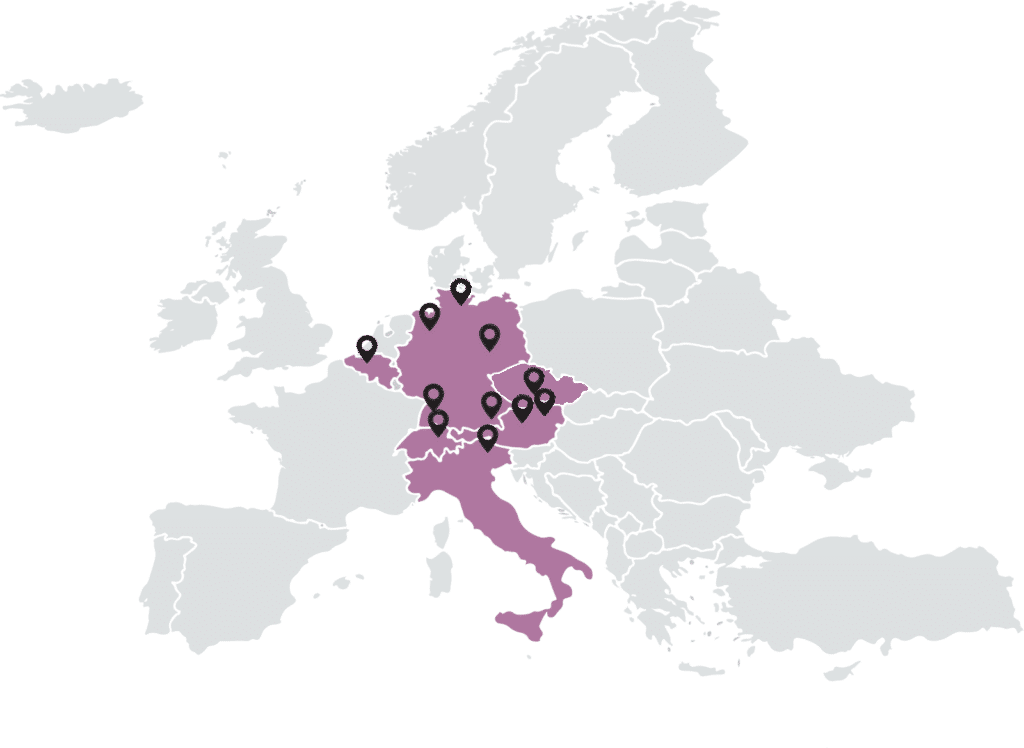

Eleven licence partners in six different countries are currently working successfully with the REPRECT TOPSTEPS-system. Together, they produce around 20,000 REPRECT TOPSTEPS-Stairs.

We are looking for more innovative and future-orientated companies that want to achieve or expand a leading position in their staircase market with the latest technology. Become part of our network and benefit from our expertise and our high-quality solutions.

The business model of REPRECT is based on the granting of licences and the sale of production hardware and software as well as special components for the implementation of the new technology. In return, the partners receive the entire know-how and full support – starting with the optimised planning of the production facility, through just-in-time production technology to storage and transport systems.