Staircase formwork with REPRECT TOPSTEPS

The future of staircase production

Efficiency, quality and cost-effectiveness for your company

With REPRECT TOPSTEPS we offer a revolutionary solution for the industrial production of precast concrete staircases. Regardless of whether your company already produces stairs or wants to open up new business areas – our technology optimises your processes and increases your competitiveness.

REPRECT TOPSTEPS – More than just a staircase manufacturing solution

REPRECT TOPSTEPS not only offers an innovative production method, but also revolutionises the entire production process for precast concrete staircases. Thanks to state-of-the-art technologies and a holistically optimised production cycle, we ensure outstanding efficiency and cost-effectiveness – while maintaining consistently high quality. Find out below how every management level benefits from these advantages:

Customised production

Do you know how much potential there is in your staircase production? In the construction industry, too, it is crucial to work not only efficiently but also extremely economically. With the REPRECT TOPSTEPS staircase manufacturing system, you can optimise your processes and take them to a new level.

Customised production with our integrated system makes it possible to achieve a very high level of cost-effectiveness from batch size 1, especially with our staircase formwork. For you, this means: less material consumption, shorter production times and maximum flexibility. Use this opportunity to secure a competitive advantage! Optimise your industrial production of concrete stairs now and increase your profits.

Get in touch with us and find out how REPRECT TOPSTEPS generates advantages for your company!

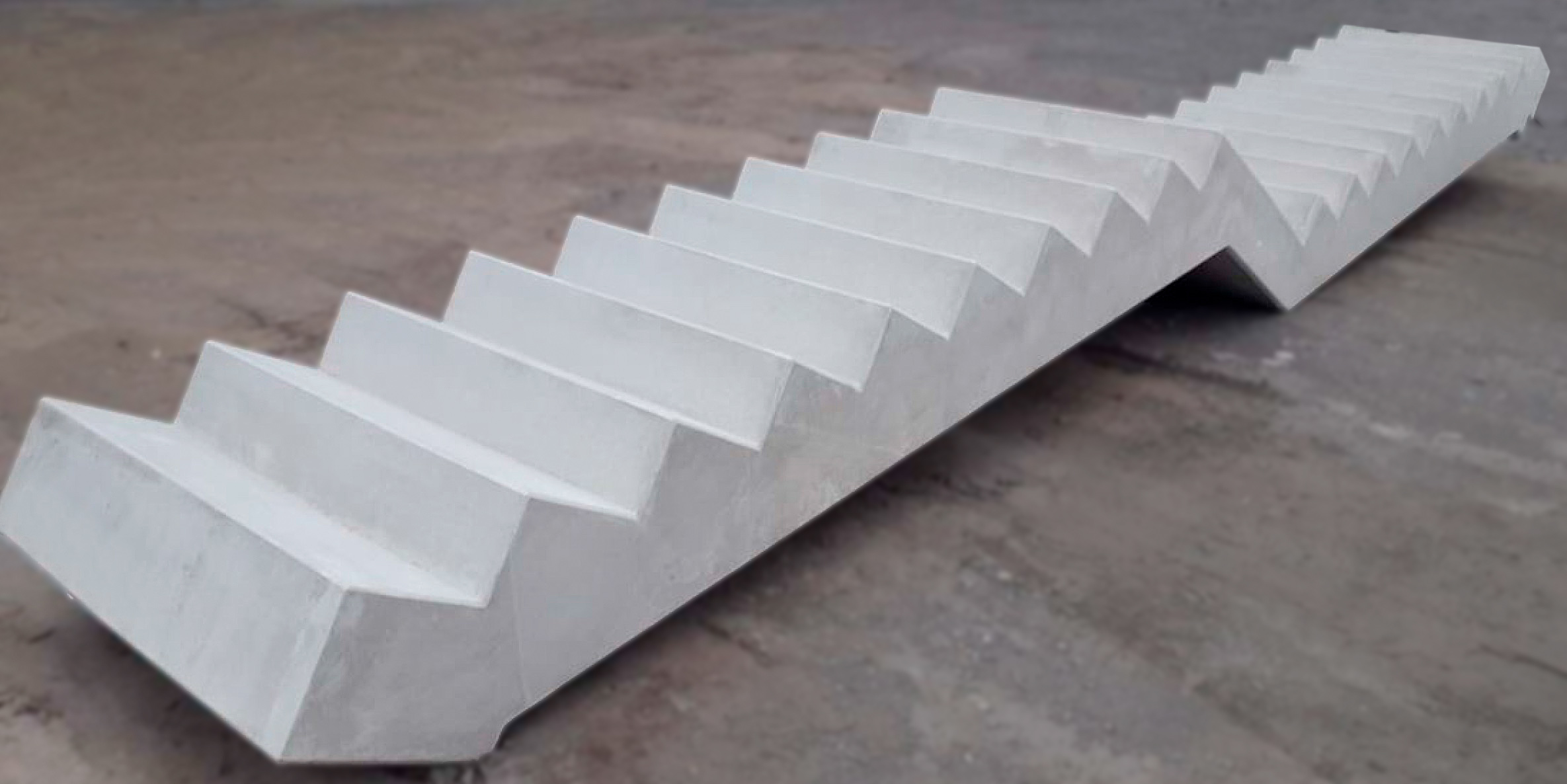

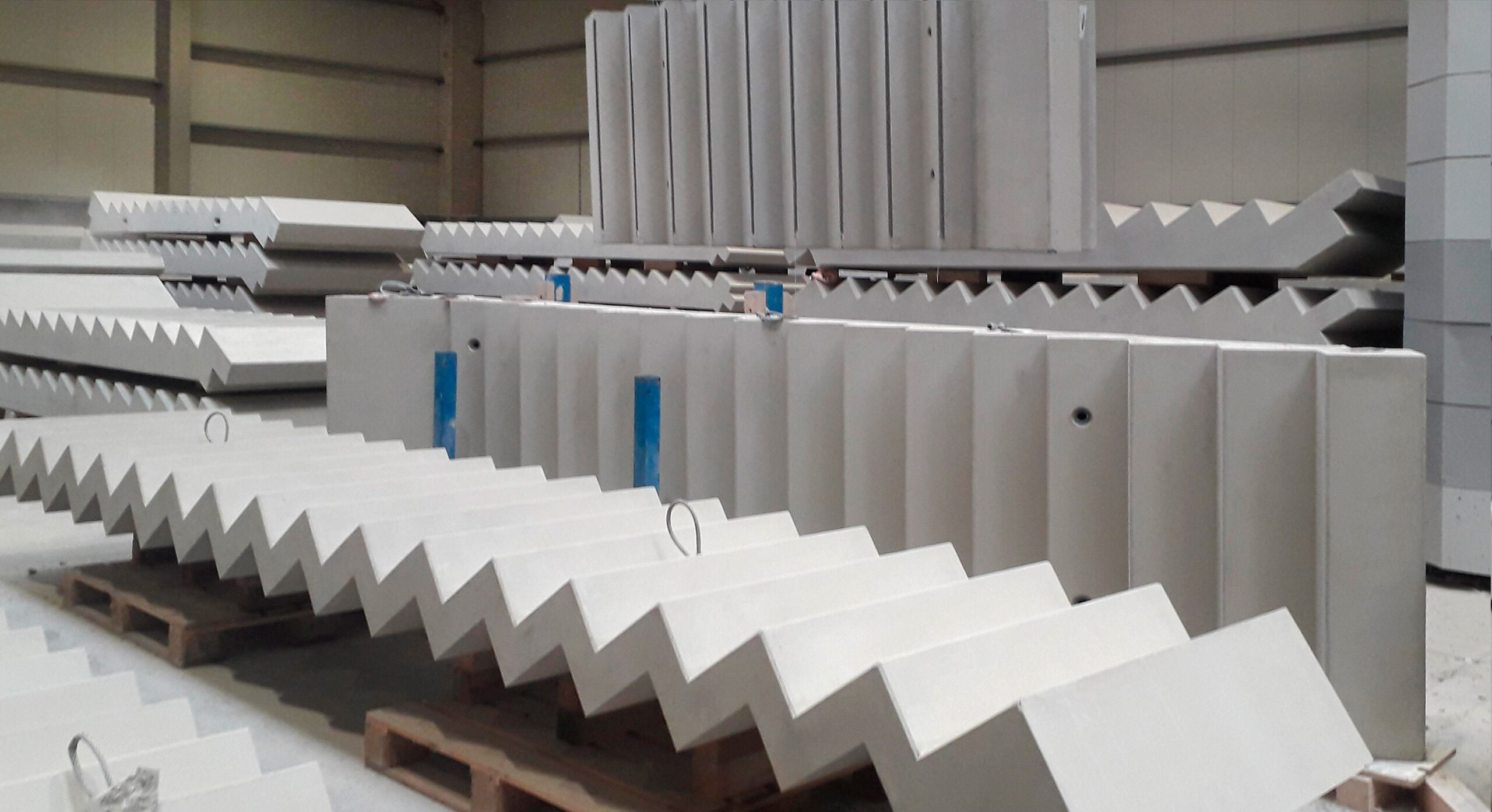

The REPRECT system enables economical, flexible and customised production of precast concrete staircases – in both straight and spiral forms, even for batch sizes of 1. Thanks to software-supported planning and modular formwork technology, individual staircase requirements can be implemented precisely and cost-effectively.

Solutions:

Straight stairs:

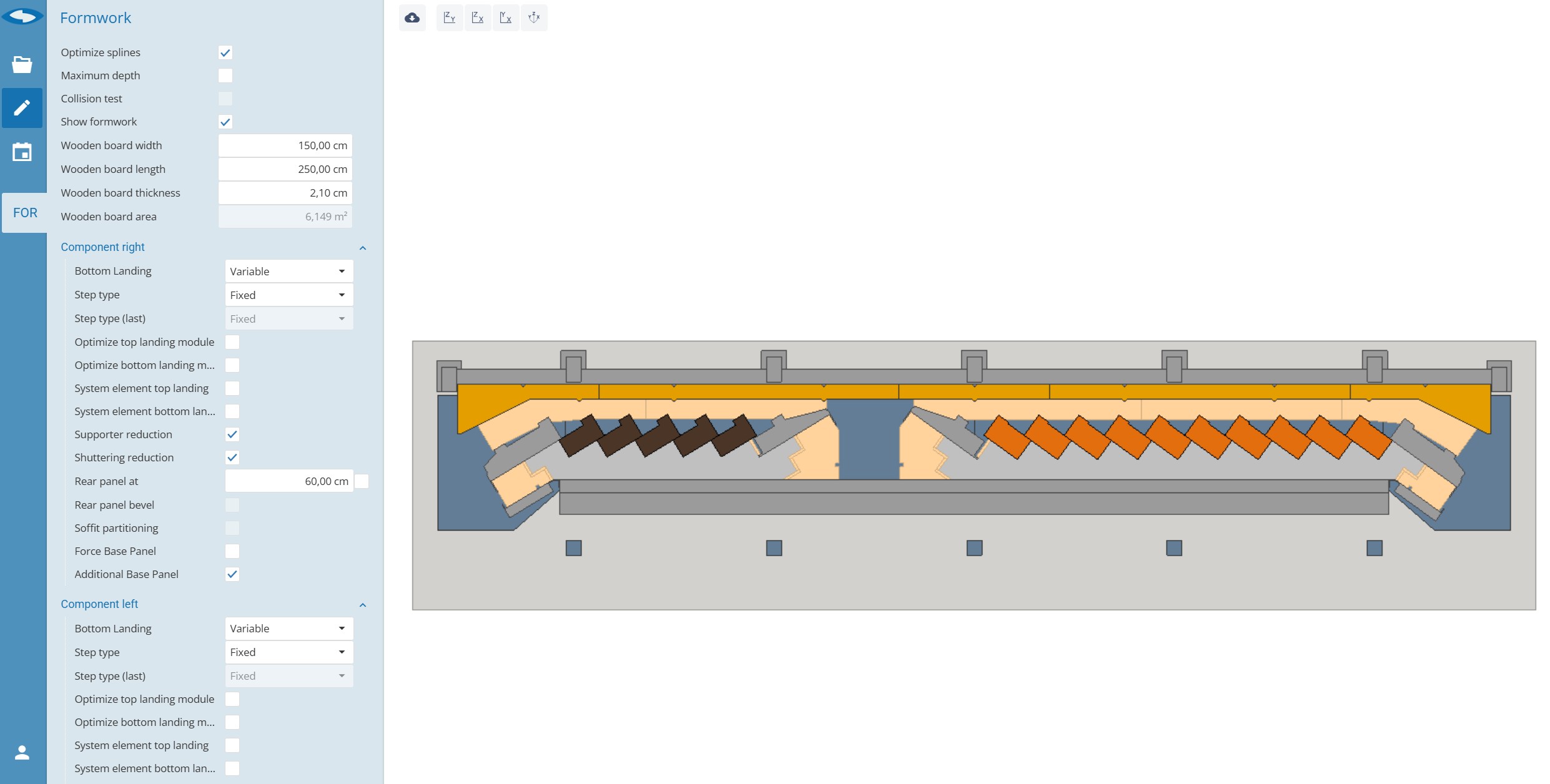

- Patented, highly flexible formwork system, which enables formwork readjustments in the shortest possible time.

- Our steel system step cores mean that no timber additions are required.

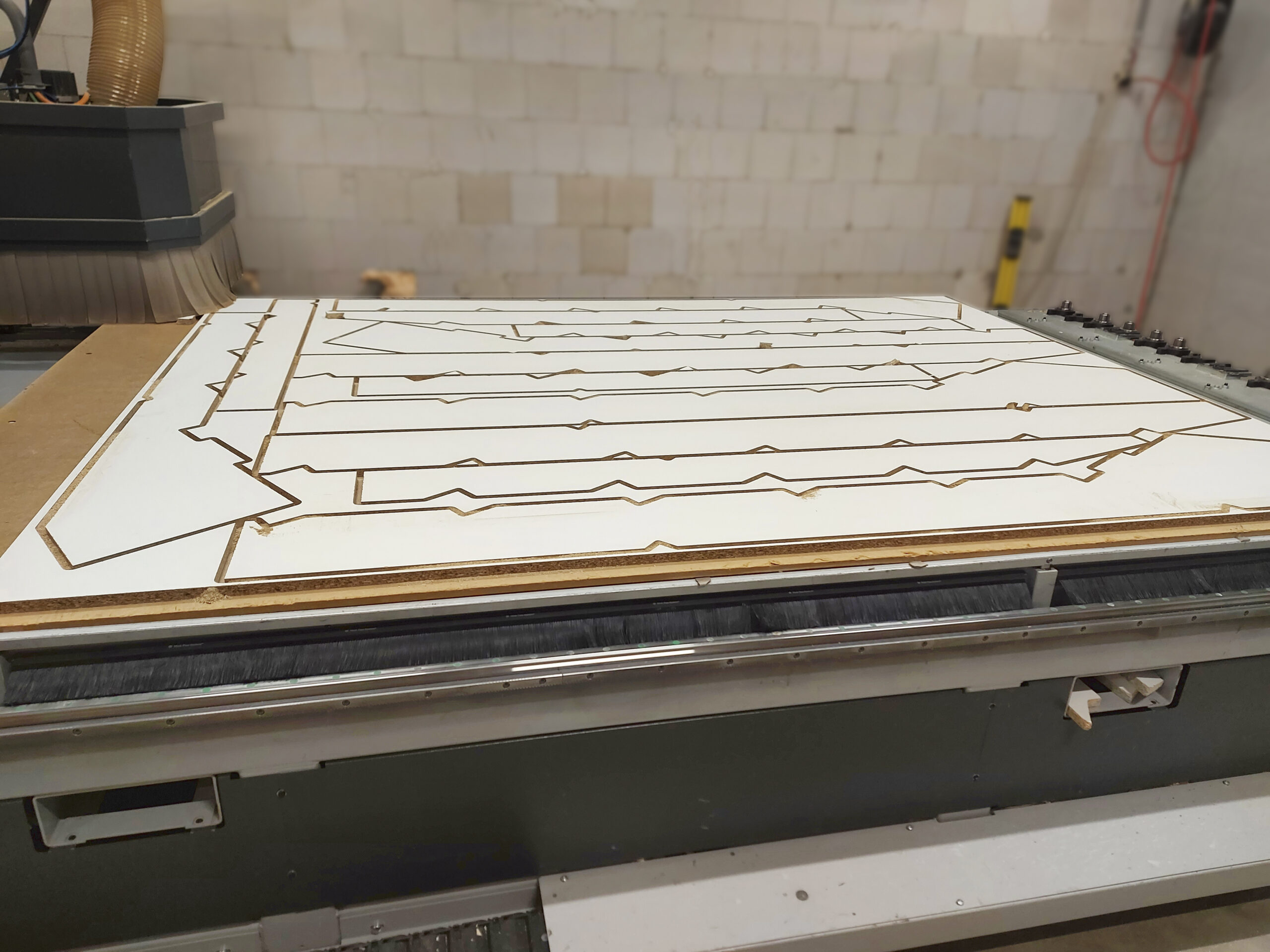

- Production of the required wooden inlay boards and end formwork using automated CAD-CAM data generation with maximum fitting accuracy in the millimetre range.

- Possibility to produce two staircases with different geometries in one mould at the same time. (double installation)

- Patented reinforcement technology (incl. type statics) based on Eurocode 2.

- Reinforcement production supported by automatic template with interface to REPRECT TOPSTEPS software

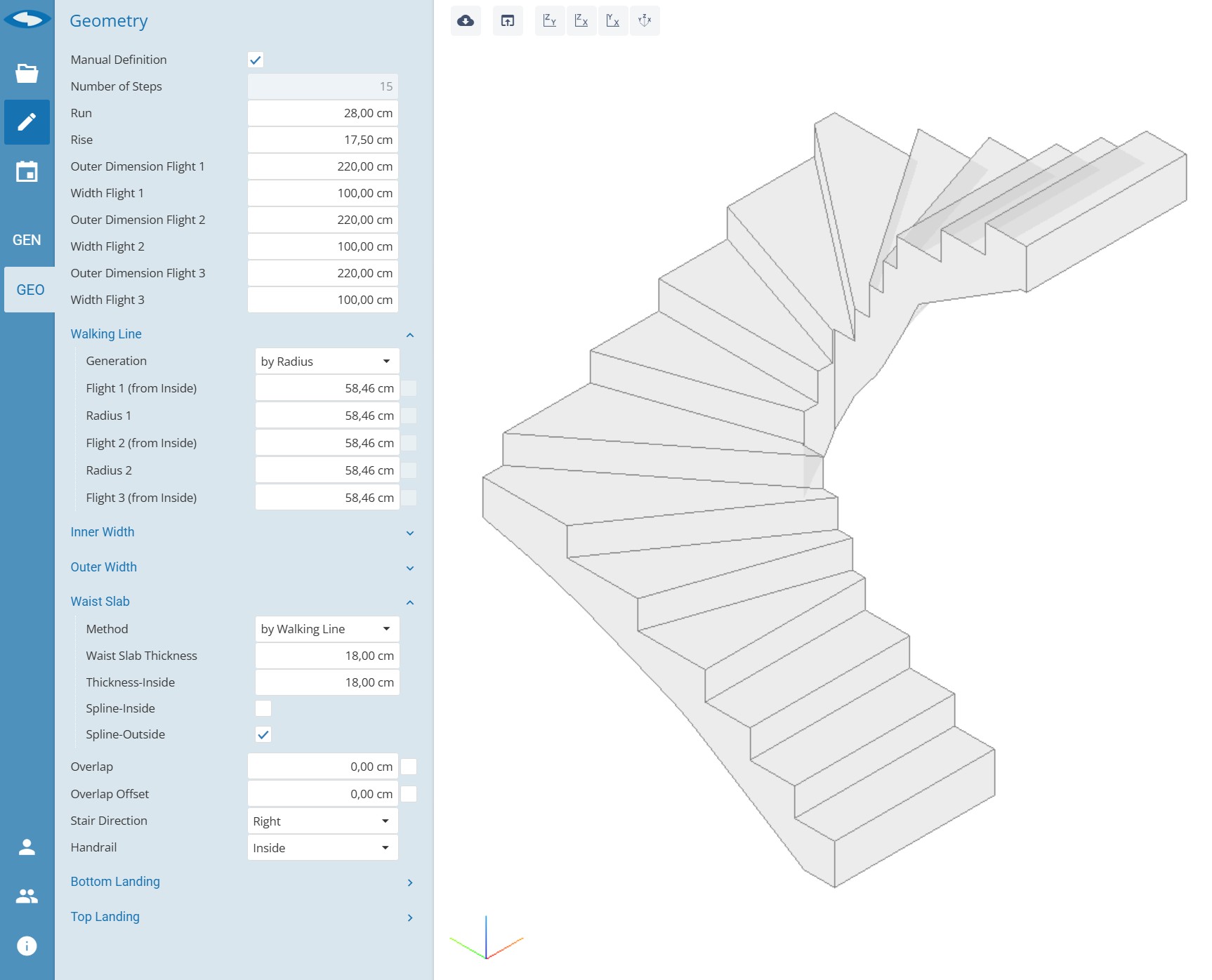

Winding stairs:

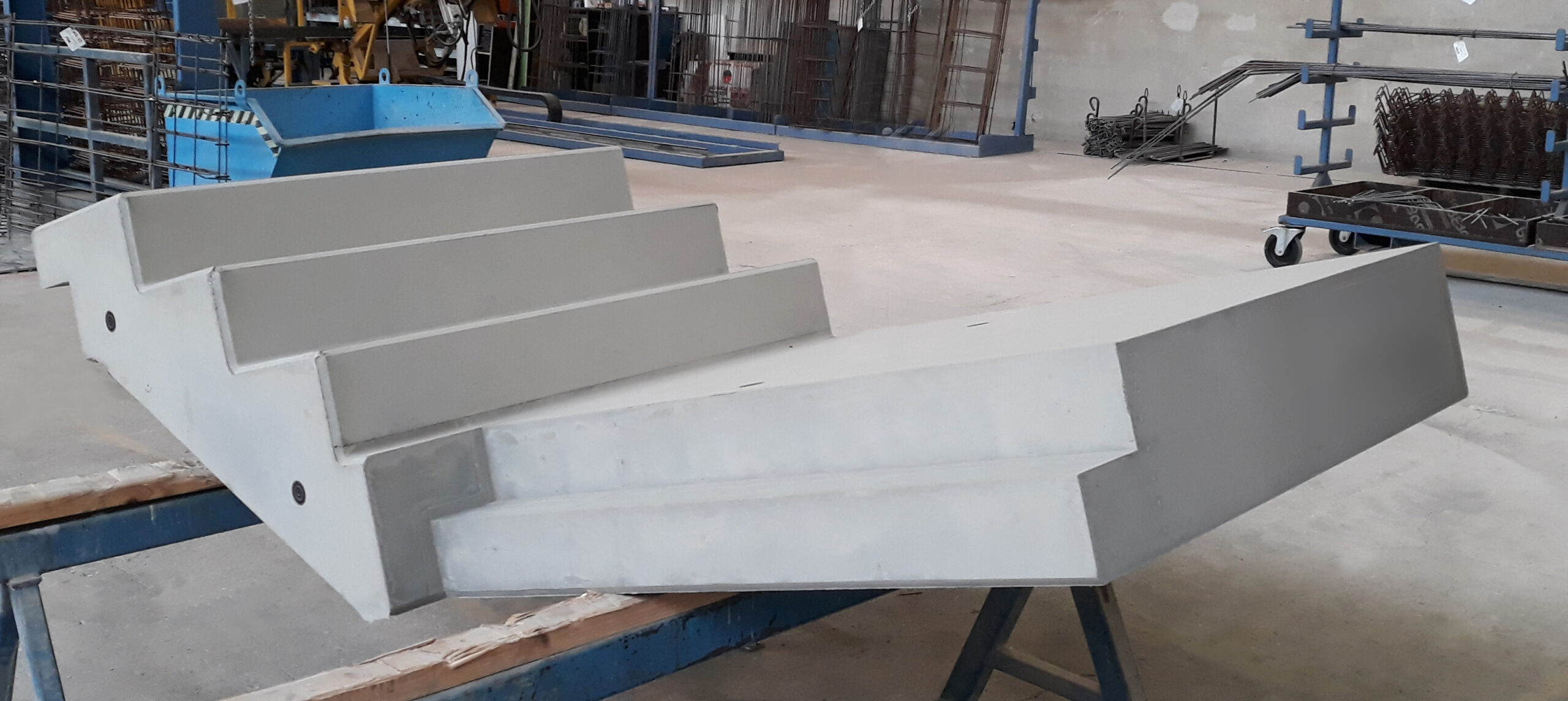

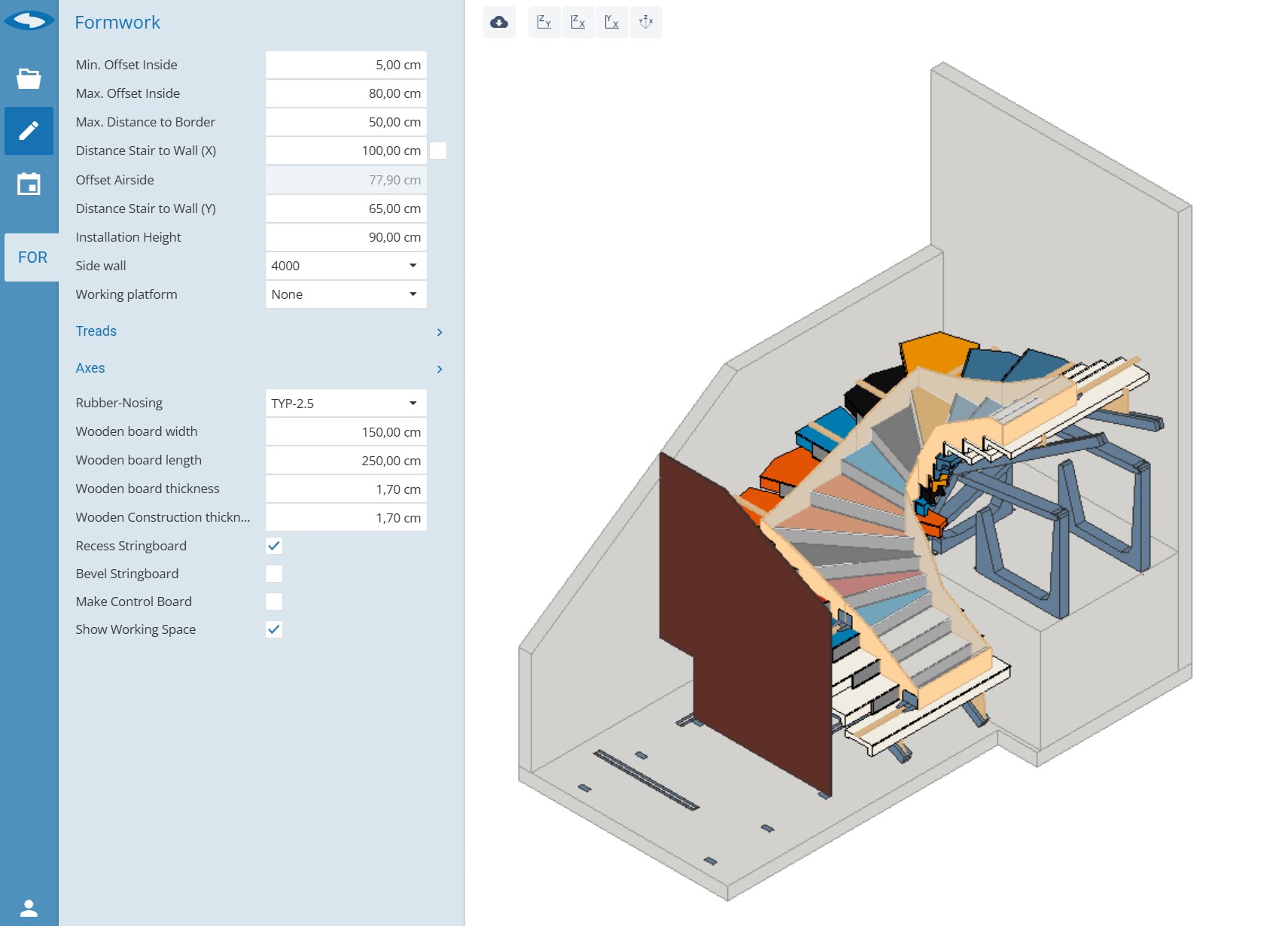

- Patented, highly flexible formwork system, which enables formwork readjustments to be made in the shortest possible time while taking work safety into account.

- Adjustable, modular steel substructure for optimum adaptation to different geometries.

- Automatic generation of all data required for formwork construction and formwork settings by the REPRECT TOPSTEPS software.

- Our steel system step cores mean that no timber additions are required.

Generate production data automatically

In today’s industry, it is crucial to work efficiently and error-free.

Traditional manufacturing with conventional staircase formwork can often be characterised by challenges such as inaccuracies, high error rates and inefficient processes. Especially in a field where precision and reliability are paramount, this can have a significant impact on your productivity and ultimately your competitiveness.

With our system, you can automate the entire production process for your concrete stairs. This is possible with our REPRECT TOPSTEPS staircase production system! The software generates all production data fully automatically and makes it easy to enter the staircase parameters – anytime and anywhere. Even with less qualified personnel, the error rate is drastically minimised.

It is currently possible to process up to 80% of all staircase types fully automatically. Use this opportunity to optimise and revolutionise your planning and production of precast concrete stairs and secure a decisive competitive advantage!

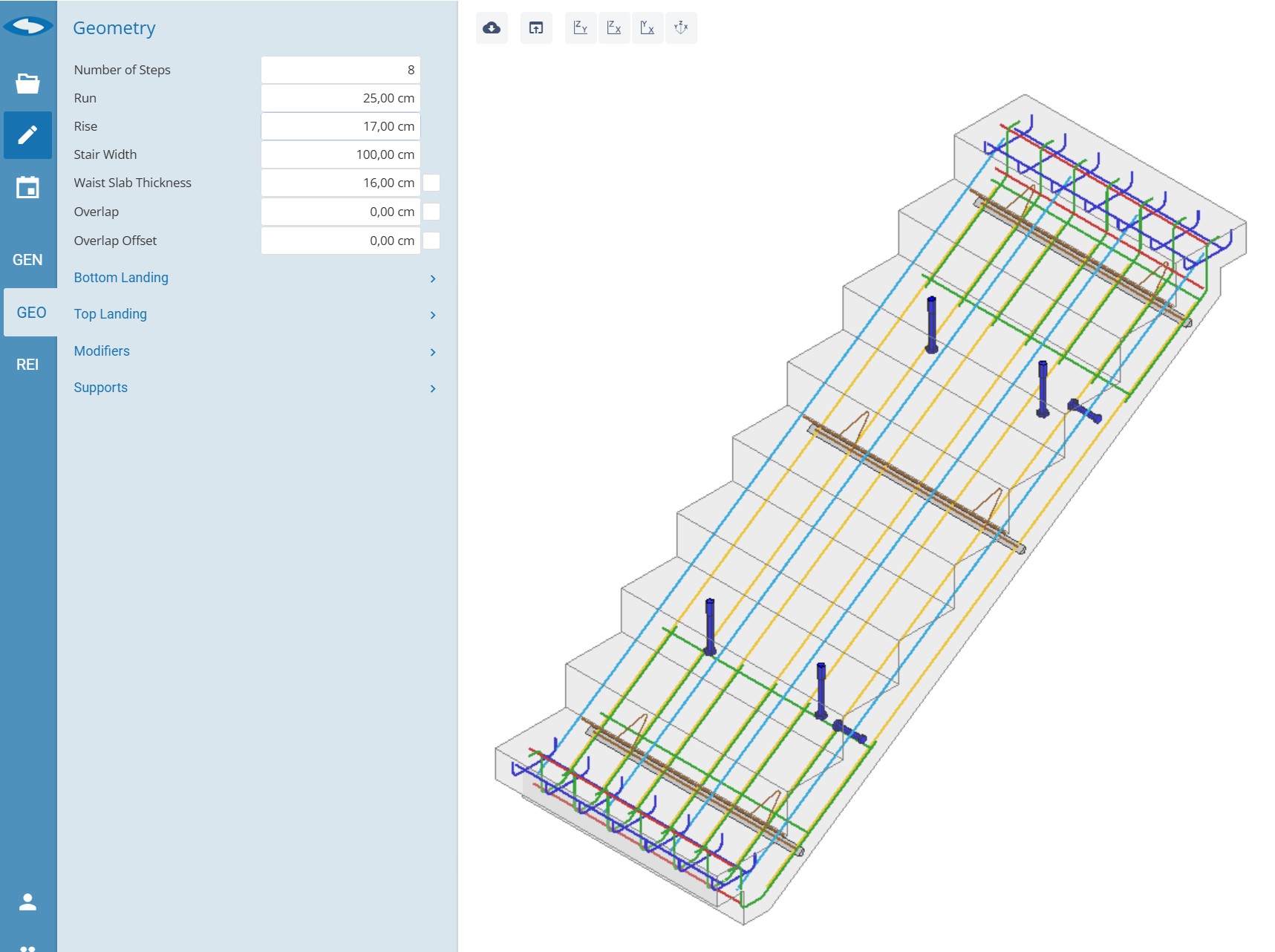

The REPRECT TOPSTEPS software creates all production data fully automatically.

Once the staircase parameters have been entered, the software generates geometry and reinforcement plans, formwork plans and CNC machine data. This reduces sources of error, enables standardised production and ensures precise implementation of the production steps.

Solutions:

Straight stairs:

- Fully automatic creation of geometry, reinforcement and formwork plans, as well as machine data (e.g. CNC milling machine).

- Predefined parameters for different staircase configurations significantly reduce the planning effort and minimise sources of error

Winding stairs:

- Fully automatic creation of geometry, (reinforcement) and formwork plans as well as setting and machine data (e.g. CNC milling machine).

- Predefined parameters for different staircase configurations significantly reduce the planning effort and minimise sources of error

Pre-Cast Server

The Pre-Cast Server is a web-based application in which all necessary production data (construction, reinforcement and formwork plans, machine data, PDFs, 3D models, etc.) are automatically generated by means of parameter input (geometry and stair requirements).

To create the data, the stair geometry must be known in advance.

Standard languages = German and English

Just-in-time production

Conventional staircase production often requires high stock levels and long lead times, which results in high costs and can delay projects. Do you know how much time and money you could save in staircase production and staircase formwork if you optimise your processes?

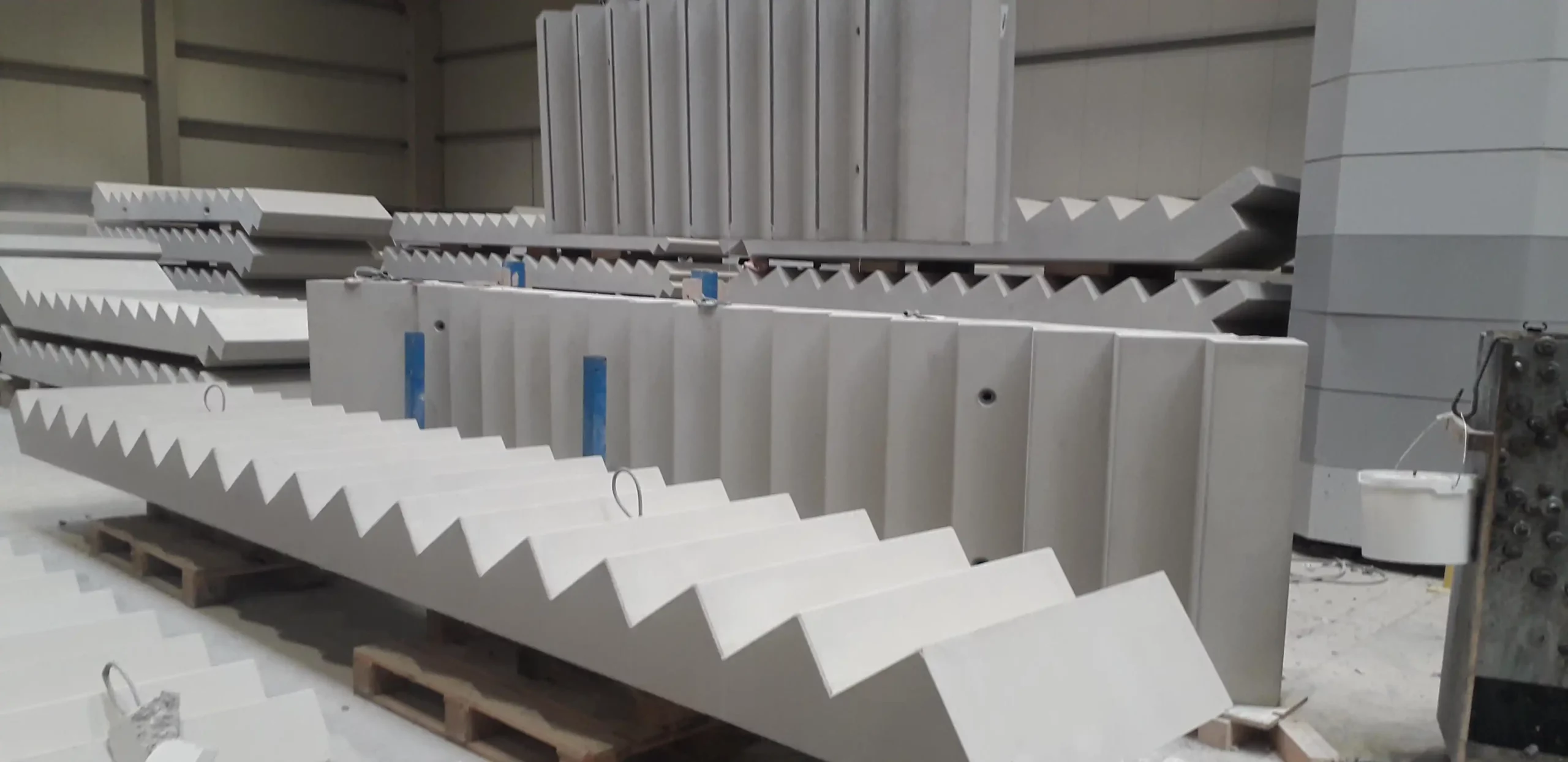

Just-in-time production becomes reality with our innovative staircase formwork and a system that covers the entire production area! Imagine: plan today, manufacture tomorrow, deliver the day after tomorrow – no more warehousing! This means a considerable improvement in your production processes, which reduces your costs and increases your competitiveness.

Take advantage of the benefits of industrial production of concrete stairs now and revolutionise your projects. Contact us for more information on our solutions and find out how we can help you take the next step in your staircase production!

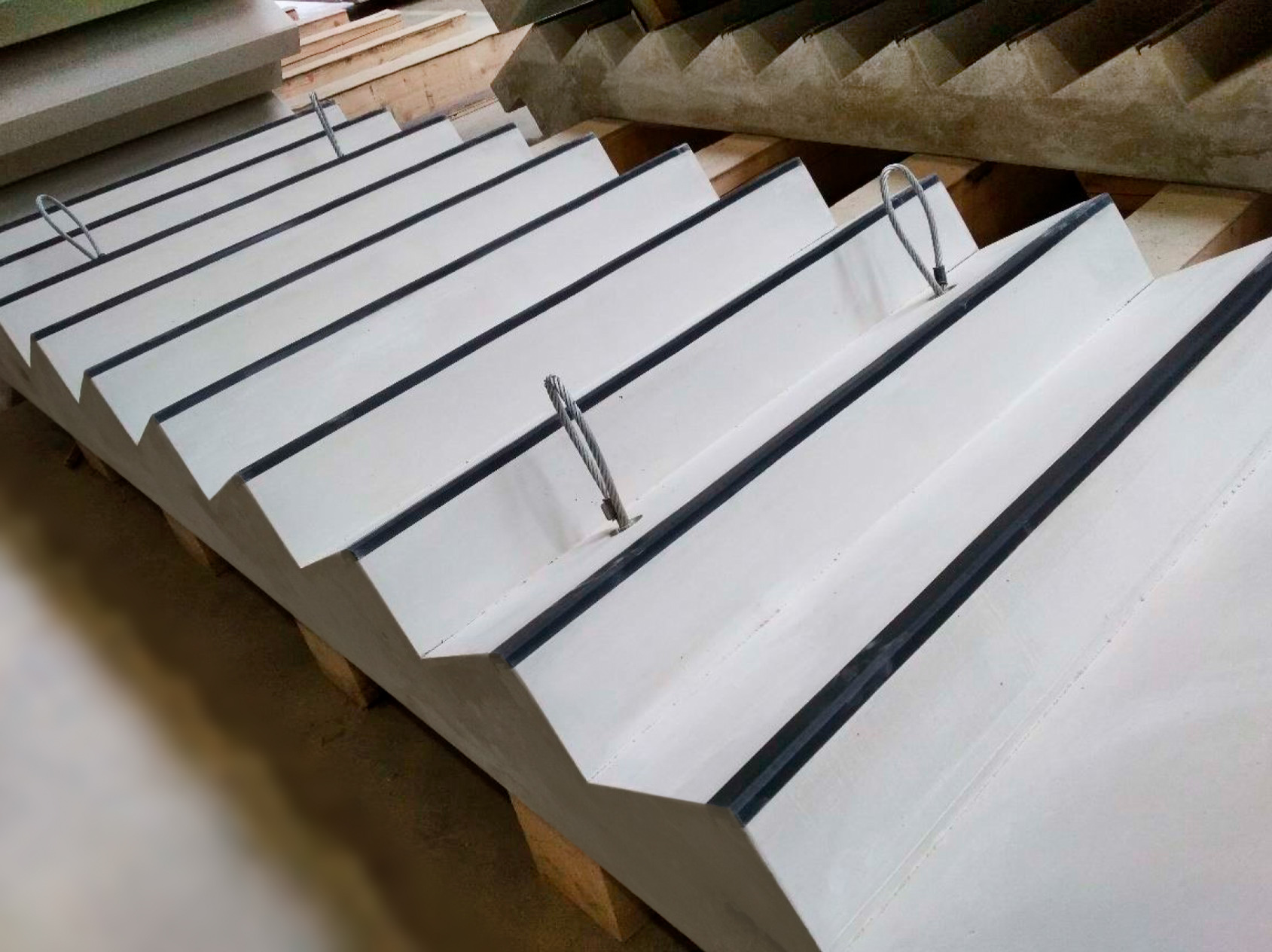

Thanks to its own REPRECT TOPSTEPS software, the flexible formwork system and optimised reinforcement technology, the REPRECT system enables just-in-time production. Thanks to the optimised reinforcement technology and short formwork changeover times, staircases can be produced with a short lead time exactly as required. This reduces storage costs and optimises the entire production process.

Solutions:

Straight stairs:

- Fast and flexible resetting of the staircase formwork thanks to minimised set-up times.

- Efficient prefabrication of reinforcement cages outside the formwork to speed up the manufacturing process.

- Shorter production times thanks to precisely defined work steps and automation of sub-areas

Winding stairs:

- Fast and flexible resetting of the staircase formwork thanks to minimised set-up times.

- Efficient prefabrication of reinforcement cages outside the formwork to speed up the manufacturing process.

- Shorter production times thanks to precisely defined work steps Automation of sub-areas

Increase personnel efficiency

Nowadays, companies in the production of concrete stairs are facing enormous challenges. The shortage of skilled labour is worsening and the need to work more efficiently is becoming increasingly urgent. You have probably already thought about how you could optimise the entire staircase production process, and staircase formwork in particular, to meet these challenges.

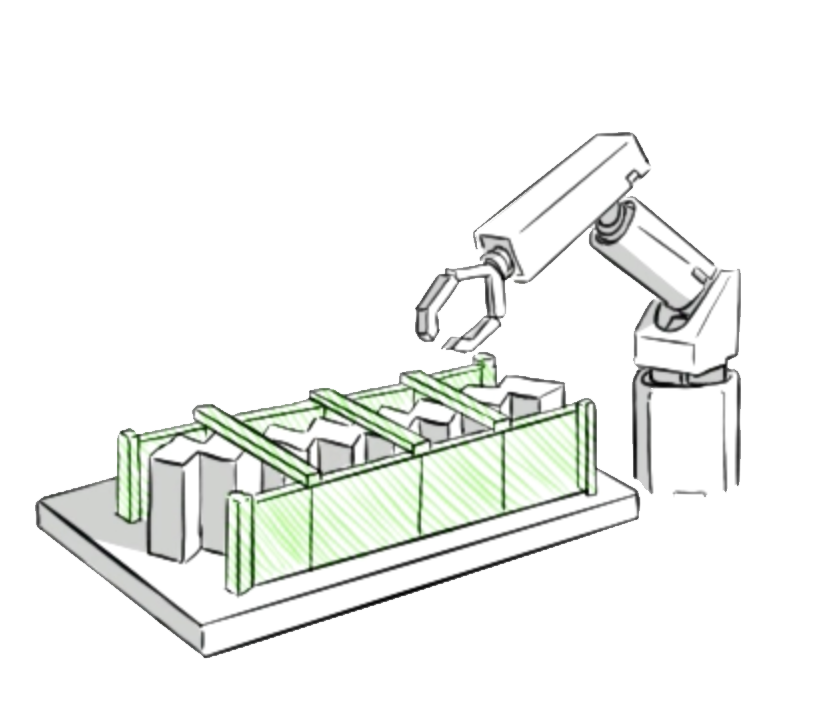

With the REPRECT TOPSTEPS system, we offer you a solution that not only increases your personnel efficiency, but also revolutionises the entire production process. All the necessary work steps can be carried out by just one person – without any special qualifications! This is not only an effective response to the shortage of skilled labour, but also enables you to produce with less physical strain.

Thanks to production on a level hall floor, you also benefit from an ergonomic working method and increase your efficiency at the same time. With just one employee, you can produce up to two staircases per day, from raw steel to delivery on the lorry. This means up to 50% less labour costs for your company!

Rely on innovative solutions and optimised equipment for more work safety and efficiency in your production. Contact us and find out how REPRECT TOPSTEPS can significantly improve your production processes!

The system’s high degree of automation significantly reduces labour costs. All work steps are designed so that they can be carried out by a single person. The production of the reinforcement outside the formwork enables parallel work processes and eliminates waiting times.

Solutions:

Straight stairs:

- Integrated air cushion system facilitates the handling of the stair mould and enables it to be handled by a single person.

- Templates for the production of reinforcement and formwork components, for fast and precise staircase production.

- Modular formwork components enable easy-to-understand and error-free handling.

Winding stairs:

- Mechanically adjustable formwork elements enable flexible, time and material-saving adjustment of the formwork readjustment.

- Flexible work platforms and safety equipment increase the ergonomics and safety of employees.

- Reduction of manual work steps through high automation and optimised processes in planning and production

More sustainable production

The construction industry is facing an urgent challenge: the need to operate more sustainably and increase efficiency at the same time. Conventional staircase production not only causes high material costs, but also considerable CO₂ emissions. With the innovative staircase production system from REPRECT TOPSTEPS, you can effectively meet these challenges.

You could realise savings of up to 70% for wood and up to 50% for steel in the adjustment or production of the staircase formwork – and at the same time achieve a CO₂ emission reduction of up to 50% for steel.

These savings are not utopian, but a tangible reality thanks to our sustainable staircase technology.

In addition, the industrial production process enables a reduction in warehousing and production errors. This not only means cost savings, but also optimisation in all areas.

Take the opportunity to take your production to the next level and actively contribute to reducing your ecological footprint. Contact us and find out how REPRECT TOPSTEPS can revolutionise your projects!

REPRECT’s innovative reinforcement technology reduces steel consumption by up to 50 % for straight staircases, which not only cuts costs but also reduces CO₂ emissions. The optimised use of offcuts and just-in-time production, which reduces unnecessary warehousing, also contribute to sustainability.

Solutions:

Straight stairs:

- Optimised reinforcement technology reduces steel consumption by up to 50% while at the same time reducing CO₂ emissions.

- High-precision CNC processing minimises the waste of wooden components.

- Just-in-time production reduces warehousing and thus cuts energy consumption.

Winding stairs:

- High-precision CNC processing minimises the waste of wooden components.

- Just-in-time production reduces warehousing and thus cuts energy consumption.

Inspire with quality

In the challenging situation in which the construction industry finds itself, you are faced with the challenge of ensuring the highest quality in staircase production at low prices. Many companies are reaching their limits with conventional methods, especially as they usually only consider the staircase formwork. Insufficient quality could jeopardise their sales and customer relationships.

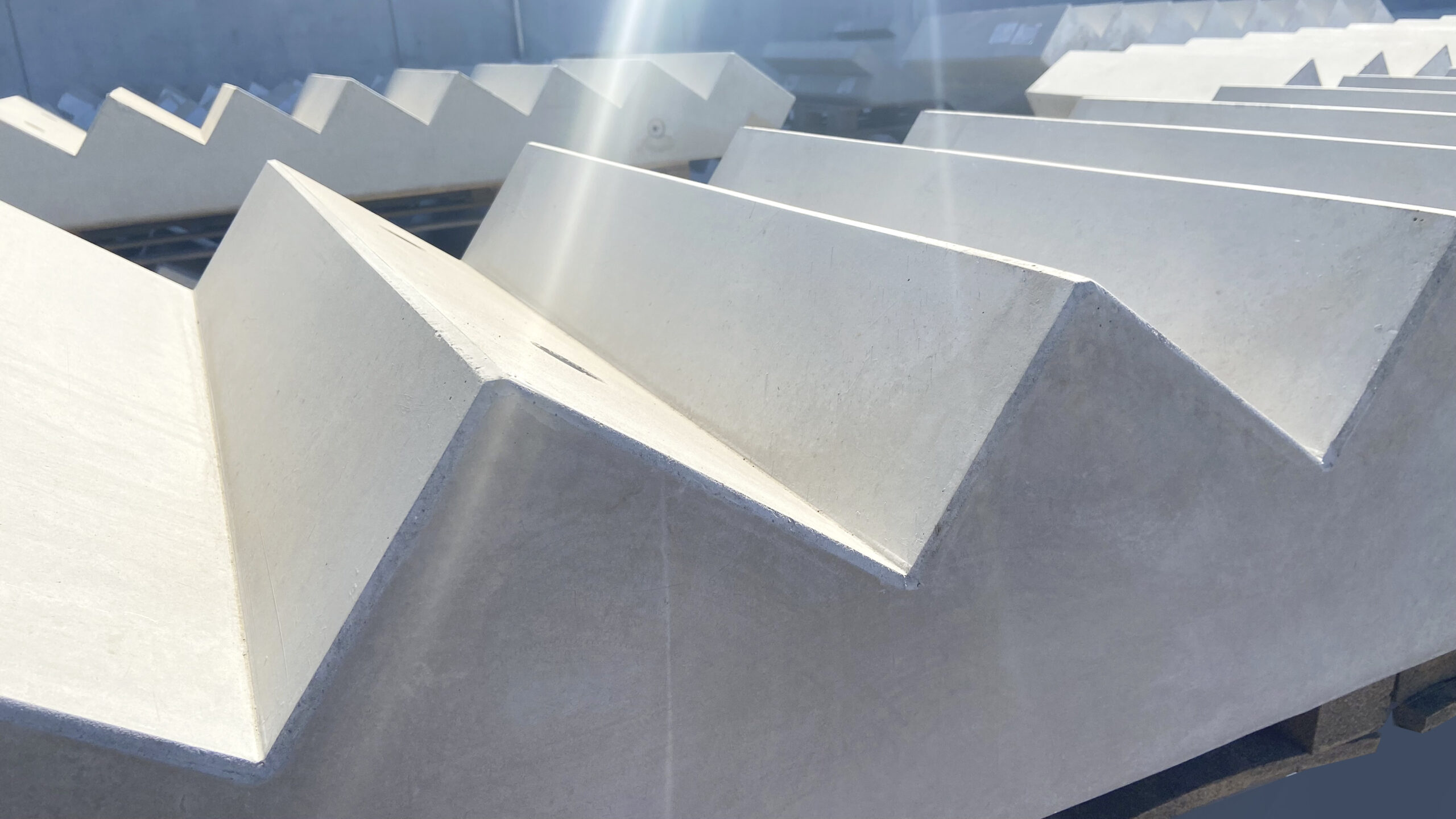

The REPRECT TOPSTEPS system offers you a solution to these challenges. The innovative technology enables us to produce a five-sided clean surface with exact stair geometry and optimum reinforcement position. Our industrial production technology ensures that all tolerances are adhered to – which means less rework and greater customer satisfaction.

Optimise your production processes with our staircase production system and experience the benefits of a special reinforcement and production technology that not only saves you time, but also money. Act now to meet the standards of tomorrow! Contact us for more information and rely on the highest quality with the industrial production of concrete stairs!

Thanks to industrialised production with REPRECT, precast concrete stairs are produced with smooth surfaces on five sides (straight stairs only), which minimises the need for finishing work. The optimised reinforcement technology ensures precise dimensional accuracy. This results in first-class staircases that meet the highest quality standards.

Solutions:

Straight stairs:

- Smooth surfaces on five sides for an excellent appearance and minimised finishing thanks to production in upright position.

- Precise reinforcement technology ensures that the concrete cover is precisely maintained.

- Standardised production processes and modular formwork components ensure consistently high production quality.

Winding stairs:

- Standardised production processes and modular formwork components ensure consistently high production quality.