Maximise your company’s success with REPRECT TOPSTEPS

The future of staircase production

Solutions for managing directors and owners

With REPRECT TOPSTEPS invest in a revolutionary solution that combines efficiency, top quality and cost-effectiveness in one. Whether your company is already established in staircase production or you are a managing director or owner looking to open up new areas of business – our technology increases your competitiveness and ensures future-oriented success.

- Strategic investmentOpen up new markets and strengthen your market position with state-of-the-art production technologies.

- Added value and ROI: Benefit from a holistically optimised production cycle that reduces costs and maximises profits in the long term.

- Innovation leadership: Position your company as a pioneer in the industrialisation of construction services with precast concrete elements.

Experience how REPRECT TOPSTEPS takes your company to the next level – efficiently, economically and future-proof.

Maximum efficiency and new market opportunities

As a managing director or owner, you are faced with the challenge of making your company future-proof and profitable. REPRECT TOPSTEPS supports you in this:

- Cost savings of up to 50 % – Less material consumption (up to 50 % less steel, 70 % less wood), lower labour costs.

- New market segments open up – Produce high-quality staircases efficiently, even if your company did not previously manufacture staircases.

- Sustainability as a competitive advantage - Reduced CO₂ footprint thanks to resource-saving production.

- Planning security through automation – reliable production times and calculable cost structures.

Conclusion: REPRECT makes industrial staircase production profitable even for companies that previously had no experience or success with staircases.

Strategic advantages for your company

Industrial manufacturing:

- Optimisation of processes: The precisely coordinated production process reduces REPRECT TOPSTEPS The result is a considerable reduction in material and, in particular, labour costs. Standardised, industrial production not only reduces errors, but also creates economies of scale that lead to considerable cost savings – even from batch size 1.

- Flexibilisation of new business areas: Even companies that have not previously manufactured stairs can usefully supplement their product portfolio and enter the staircase market – with a proven, particularly economical solution that fulfils the highest quality requirements.

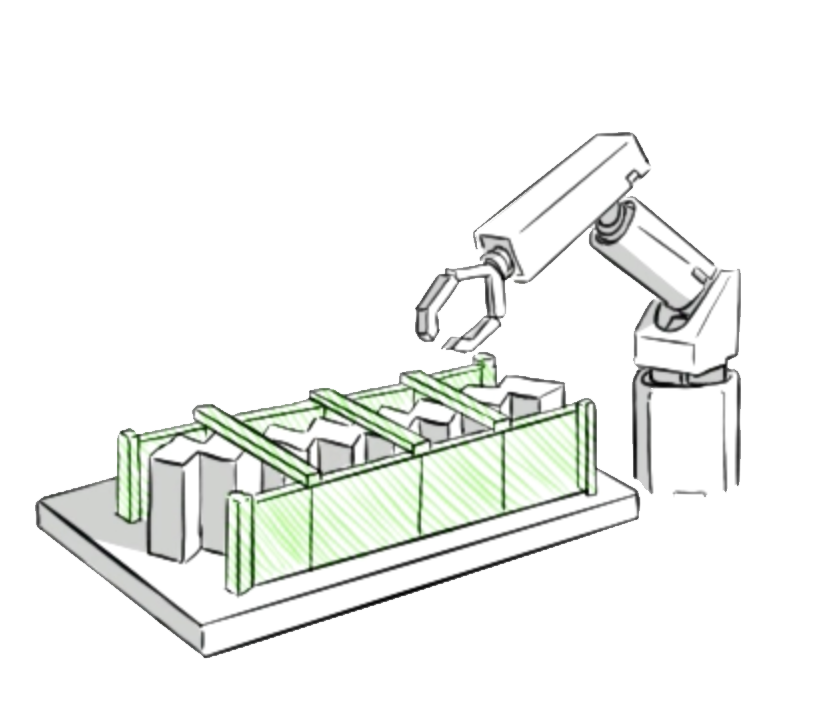

Automation:

- Comprehensible processes: Automated processes minimise human error and ensure that all production steps are precisely adhered to. This means reliable and predictable costs and performance.

- Technological pioneering role: Investing in modern automation strengthens your company’s innovative profile and positions you as a technology leader in the industry.

Just-in-time production:

- Calculable supply chains: The REPRECT TOPSTEPS system enables just-in-time production, eliminating expensive warehousing and handling costs. You receive your products exactly when they are needed – which reduces capital commitment and creates flexibility in production.

- Speed of reaction: Flexible production planning makes it possible to react quickly to changes in the market. This gives your company a decisive competitive advantage.

Personnel:

- Efficient use of resources: Thanks to a one-person operation in the individual work areas, staff requirements are significantly reduced – a decisive advantage in times of a shortage of skilled labour.

- Cost savings: Lower personnel deployment leads to a reduction in labour costs and easier planning of employee resources.

Sustainability:

- Conservation of resources: Thanks to the optimised use of materials, up to 50 % less steel and up to 70 % less wood is used for straight staircases. This not only has a positive effect on production costs, but also strengthens your company’s environmental profile.

- Reduced CO₂ footprint: Sustainable production processes and reduced material requirements lead to significant CO₂ savings – a strong argument in today’s environmentally conscious business world.

Quality:

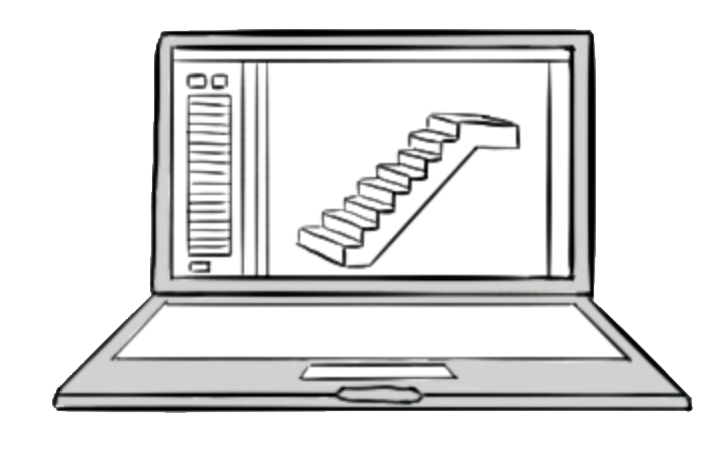

- Consistent top quality: Parameterised data acquisition and automated data processing ensure that tolerances are maintained and faulty products are virtually eliminated. A five-sided shell-clean surface and precise staircase geometries are the hallmarks of the REPRECT-technology.

- Competitive advantage: High and comprehensible quality standards increase the trust of your customers and strengthen the market position of your company.

Conclusion: One system – three perspectives

REPRECT TOPSTEPS provides for all decision-makers is a forward-looking solution for companies that produce prefabricated structural components. Whether you are a managing director looking to strategically reduce costs and tap into new market potential, a technical manager relying on precise and reliable processes or a production manager or plant manager looking to increase daily efficiency and make optimum use of human resources – our solution offers you tailor-made benefits in the areas of industrial production, automation, just-in-time production, personnel optimisation, sustainability and quality.

Arrange a consultation appointment and let us convince you of the many advantages!