Technological excellence for your processes with REPRECT TOPSTEPS

Precision in staircase production

Solutions for technical managers

With REPRECT TOPSTEPS you as a technical manager can rely on state-of-the-art technologies that revolutionise the entire production process for precast concrete staircases. Our solution optimises every work step – from precise planning to highly automated production – and guarantees the highest quality and efficiency.

- Innovative production methodsUse digital and automated processes to optimise production cycles.

- Process optimisation: Benefit from a holistically optimised production process that masters technical challenges and meets future requirements.

- Technological progressIntegrate state-of-the-art systems that not only raise the current standard, but also support future-oriented developments.

Control your production with precise technology and innovative approaches for a production process that sets standards.

REPRECT TOPSTEPS – More than just a staircase manufacturing solution

REPRECT TOPSTEPS not only offers you, the technical manager, an innovative production method, but also revolutionises the entire production process for precast concrete staircases. Thanks to state-of-the-art technologies and a holistically optimised production cycle, we ensure outstanding efficiency and cost-effectiveness – while maintaining consistently high quality. Find out below how every management level benefits from these advantages.

Innovative processes and maximum precision

Are you responsible for technical implementation and quality assurance? REPRECT TOPSTEPS offers you an end-to-end solution for efficient and error-free staircase production:

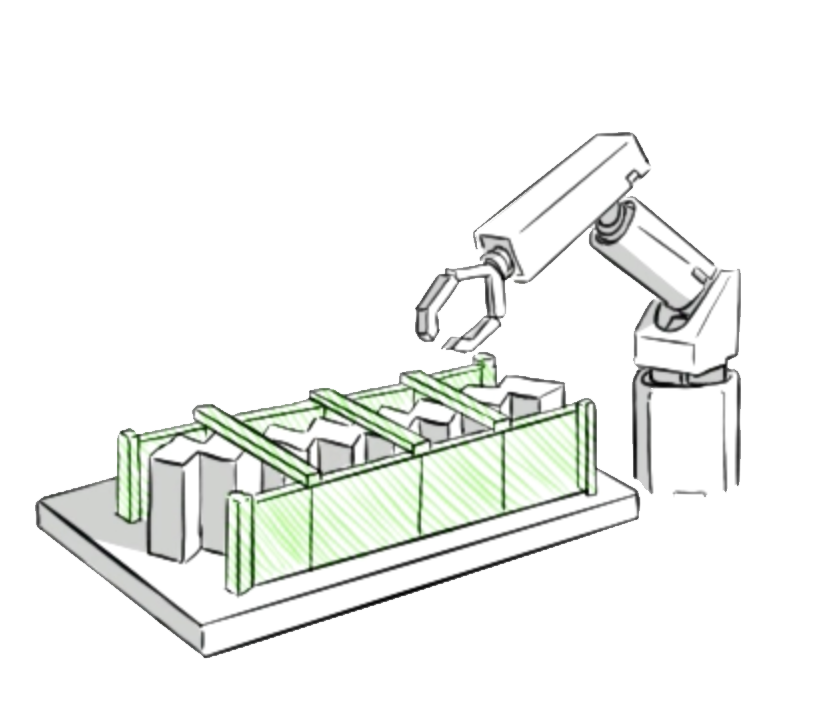

- Automated planning & production – Fully automatic generation of all production data reduces errors and increases precision.

- Exact stair geometry & reinforcement – Industrial production technology ensures compliance with all tolerances.

- Flexibility with batch size 1 – Customised production without expensive additional work.

- Quality guarantee – 5‑sided clean surfaces and optimised concrete cover for perfect results.

Conclusion: REPRECT TOPSTEPS combines innovation with safety – for smooth production with maximum precision.

Precision and process reliability at the highest level

Industrial manufacturing:

- Standardised processes: The industrial production of REPRECT TOPSTEPS enables virtually error-free production. Each staircase is manufactured according to precisely specified processes – this minimises deviations and facilitates quality control.

- Optimised production processThe end-to-end production process avoids interface problems, resulting in a smooth transition from planning to structural design and production.

Automation:

- Integrated software solutions: With our fully automated software, all staircase parameters are simply entered and converted directly into production data. This reduces manual input errors and speeds up the entire production process.

- Technological perfection: Clearly defined and partially automated processes ensure that even complex staircase shapes (both straight and spiral) are realised precisely – a decisive advantage for technical managers who are responsible for compliance with technical standards.

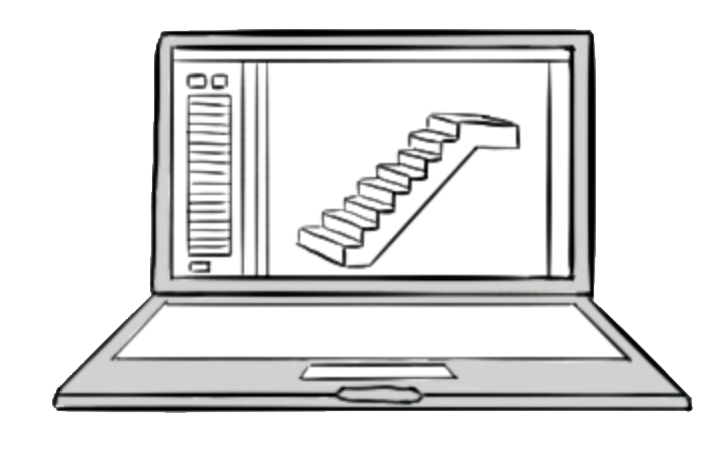

Pre-Cast Server

The Pre-Cast Server is a web-based application in which all necessary production data (construction, reinforcement and formwork plans, machine data, PDFs, 3D models, etc.) are automatically generated by means of parameter input (geometry and stair requirements).

To create the data, the stair geometry must be known in advance.

Standard languages = German and English

Just-in-time production:

- Process optimisation: The REPRECT TOPSTEPS system enables just-in-time production, ensures a continuous material flow and minimises intermediate storage. This reduces waiting times and enables precise coordination of the production steps.

- Flexibility: Production close to the delivery date reduces disruptions caused by changes to deadlines.

Personnel:

- Ease of use: The intuitive operation of the REPRECT TOPSTEPS Software does not require lengthy training programmes. Even less experienced employees can quickly become productive, which simplifies internal training.

- Relief in the technical area: Automated processes reduce the need for constant checks.

Sustainability:

- Efficient material utilisation: Precise planning and production significantly reduces rejects and material losses. You benefit from a transparent process that conserves resources and reduces costs at the same time.

Quality:

- High process reliability: Standardised, automated processes ensure that quality standards are consistently maintained. Each staircase fulfils exact geometric and structural specifications, which ensures consistently high product quality.

Conclusion: One system – three perspectives

REPRECT TOPSTEPS offers Decision-makers in the production of prefabricated building components an innovative solution that looks to the future. Whether you are a managing director who wants to strategically reduce costs and open up new market opportunities, a technical manager who relies on precise and reliable processes or a plant manager or production manager who wants to increase daily efficiency and optimise the use of human resources – our solution provides you with customised benefits.

Benefit from advances in industrial manufacturing, automation and just-in-time production. We help you to optimise the use of your human resources and at the same time focus on sustainability and quality. Let’s set the course for a successful future together!

Arrange a consultation appointment and let us convince you of the many advantages!