In order to manufacture customised prefabricated staircases under industrial conditions in a particularly cost-effective manner, it was also necessary to Reinforcement technology to change.

- As part of the development, the following approaches were implemented on the basis of EUROCODES:

- Retention of the usual ribbed steel reinforcement in the respective country-specific steel grades.

- Reinforcement is only used where tension occurs in the concrete. The upper running plate reinforcement is only reinforced with manipulation or transport reinforcement.

- No edging.

- Use of type reinforcement elements.

- The TOPSTEPS reinforcement is based on test-supported static calculations by a renowned Austrian engineering firm.

- The tests were carried out as part of a research project by the Vienna University of Technology.

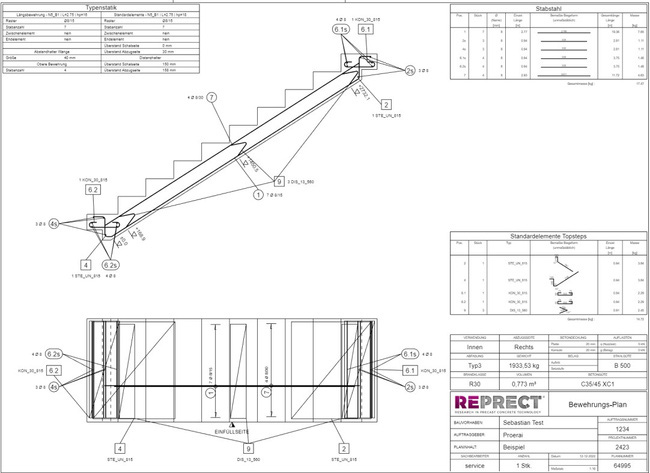

- Creation of a type statics with narrow dimensional gradations.

- The type statics are processed in a specially developed PrecastServer software („PCS”).

- Coordination and approval of the new reinforcement system by the LGA .

The Type statics was recognised in the following countries authorised/validated:

- Germany

- Belgium

- The Netherlands

- Czech Republic

- Austria

- Switzerland

- Italy

Starting in Austria in 2013, the system was gradually rolled out in the countries listed above.

The main advantages of TOPSTEPS staircase reinforcement

Technical:

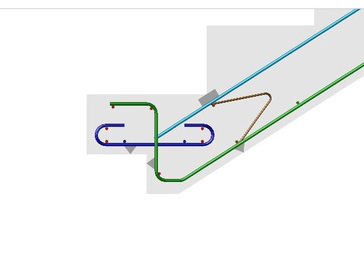

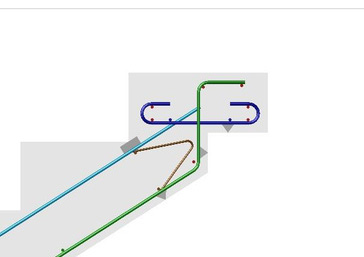

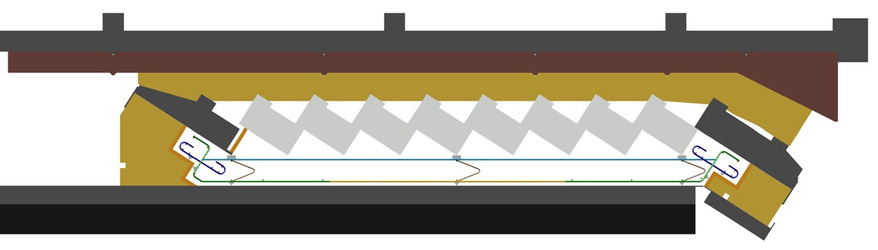

- Precise dimensions of the reinforcement cages thanks to individual elements that are assembled into reinforcement cages in a computer-controlled template. This makes it possible to produce the cages with very low (a few millimetres) tolerances.

- Ensuring the exact position of the main reinforcement with compressible spacer elements and spot-welded stainless steel spacers.

- Fully automatic generation of the reinforcement plans incl. reinforcement system using Precast Server Software (PCS).

Further advantages of TOPSTEPS staircase reinforcement

Economical:

- Reinforcement requirement reduced by up to 50 %, on average approx. 50 kg per staircase.

- Less time required to produce the reinforcement cages.

- Low planning effort in combination with the most economical design of the reinforcement.

- No „over-reinforcement”.

- Individual structural analyses and planning only required for approx. 20 % of the stairs.

Ecological:

- The type reinforcement results in an optimised reinforcement design. Together with TOPSTEPS technology, the reinforcement requirement is significantly reduced, on average by up to 50 kg.

- Depending on the steel production (new steel, recycled steel, etc.), this results in a CO2-equivalent of approx. 2.00.

- approx. 6 kWh energy saving (incl. raw steel production) per kg of reduced reinforcement = approx. 300 kWh per average TOPSTEPS staircase compared to conventionally reinforced staircases (approx. 10 TOPSTEPS staircases already save the annual electricity consumption of a normal household).

- approx. 100 kg CO2 Savings per average TOPSTEPS staircase and per fuel used (coal, coke, gas, etc.).

We and our specialists will be happy to provide you with detailed technical information.